Battery Testing Overview

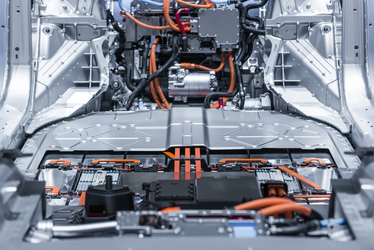

Turnkey automotive battery testing solutions for research, development and validation

Besides testing and characterization of batteries, the emulation of electric systems is becoming increasingly important.

To optimize, validate, and evaluate components and applications through reliable and flexible battery simulation, HORIBA has developed X-HVT.

X-HVT simulates the real behavior of:

With a single unit voltages up to 1500 V, currents up to 2000 A, and outputs up to 1000 kW can be achieved. Higher currents and power levels are possible through parallel configuration. Stored simulation models enable realistic battery emulation. In addition, custom discrete-time, continuous-time, or hybrid Simulink and Stateflow models can be processed.

Thanks to its modular design, X-HVT can be individually customized and configured to meet your testing requirements. It is ideally suited for testing and evaluating charging devices, inverters, and battery management systems (BMS).

Currents up to ±800 A enable the simulation of starter behaviors and start-stop scenarios. Higher values are possible with parallel setups. In addition to constant power, voltage, resistance, and performance modes, switching conditions and alarm limits can also be defined.

Stored simulation models allow for the emulation of:

Custom, time-discrete, time-continuous, or hybrid Simulink and Stateflow models can also be processed.

X-HVT is a customizable solution for diverse testing needs and includes:

For further information, please contact us — we are happy to discuss your requirements.

Charge-Discharge Unit for High Voltage Testing and Emulation

Power Rating

Overall Efficiency at Power Rating

Noise

Operating Modes

Voltage Range

Current Range

Measurement Accuracy

Resolution

Sampling Rate

Storage Rate

Cycle Time

Standard Models

Setpoint

Parameter

Frequency Range

Impedance Range

Impedance Accuracy

Phase Angle Accuracy

Max. Modulation Current

Ripple

Risk Assessment

Safety Controllers

ISO Controller

Safety Version according to ISO 13849 / EN 60204-1

Verification of the functional safety (audit trail) incl. creation of validation certificate ISO 13849

Você tem alguma dúvida ou solicitação? Utilize este formulário para entrar em contato com nossos especialistas.