Advantage

Fast and highly reliable feedback control

The RU-1000 plasma emission controller with its newly developed algorithm performs fast and highly reliable feedback control. Customers can change the PID value and thus it is possible to optimize the settings for particular conditions

Excellent S/N characteristics with plasma emission

Optimal designs are applied using collimators and other optical parts for accurately measuring slight changes in the amount of light emitted by plasma emission

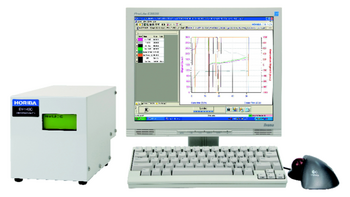

Special user-friendly software

The special software was designed while taking customer demands to heart; it promises outstanding operability. Customized software can also be developed according to customers’ needs.

Features

The RU-1000 plasma emission controller achieves excellent spatial distribution of deposition on substrates with large surface areas.

Reactive sputtering is performed for film deposition on films and glass substrates used for touch panels. This method is employed to form a deposited film by chemical reactions between sputtered particles and oxygen, nitrogen or similar in a vacuum chamber. The film deposition dramatically accelerates, in a transition region between the reactive mode and metallic mode, the latter of which results in faster film deposition. Such a transition region can be maintained by controlling the reactive gas by adjusting the intensity of plasma emission and the power supply.

The RU-1000 plasma emission controller accelerates film deposition to a pace comparable to that in metallic mode and achieves excellent deposition distribution on substrates with large surface areas. This unit captures signals representing the plasma condition transmitted from the PMT unit and plasma power supply and employs an algorithm written by HORIBA STEC to control a highly responsive mass flow controller also developed by the company.

The flow of the reactive gas is controlled to maintain the transition region between the metallic mode and reactive mode.

From plasma emission detection to gas flow, experience the latest control technologies pioneered by HORIBA STEC.

*According to survey conducted by HORIBA STEC in 2014

Application

Condition control of the vacuum chamber

Reactive sputtering with functional films or functional substrates is performed in a continuous process for a prolonged period of time. Stable film deposition processes require real-time measurement of the

changing conditions inside the vacuum chamber and the plasma emission, as well as adequate control of the flow rate of the reactive gas being introduced according to the degree of the changes.

Any process for depositing multi-layer films involves the need for increased control of the deposition rate of each film according to the rolling and conveying speed.

The RU-1000 monitors voltage signals of the impedance in the plasma power supply and the intensity of plasma emission. The feedback given to the mass flow controller based on the monitored signals

helps manufactures control the plasma emission at an optimal level and thereby enhance their productivity.

Flow controllers and plasma instruments for process optimization

An array of systems is used to measure and control the conditions inside the vacuum chamber. They ensure stable production and boost productivity by monitoring conditions inside the chamber and maintaining an optimal sputtering process.