Model | GI-700 | ||||||

Component | NOx | SO2 | CO | CO2 | O2 | NH3*3 | |

Measurement methods*1 | NDIR | NDIR | NDIR | NDIR | MPA | CLA | |

Range*1 | Standard | 10~5000 ppm | 10~5000 ppm | 50~5000 ppm | 5~25 vol% | 10~25 vol% | 10-100 |

| Optional | 5 ppm~ | 5 ppm~ | 5 ppm~ | 10 vol%~ | - | - |

Range Ratio*1 | Standard | 1:10 | 1:10 | 1:10 | 1:5 | 1:5 | 1:10 |

Optional | 1:20 | 1:20 | 1:20*2 | 1:5 | - | - | |

Indicated error | ± 1.0 % of full-scale value for each component and range (Standard range ratio) ± 2.0 % of full-scale value for each component and range (Optinonal range ratio) | ||||||

Zero drift | ± 1.0%/week of full scale (standard range) (if the ambient temperature change is ≤ 5°C) | ||||||

Span drift | ± 2.0%/week of full scale (if the ambient temperature change is ≤ 5°C) | ||||||

Response time | T90=45s from the analyzer inlet | ||||||

Interference | ±2.0% of full scale | ||||||

Environment | Temperature | 0° to 40°C (No direct sun light or no radiation heat) | |||||

Humidity | ≤ 90% | ||||||

Vibration | 100Hz, 0.3m/s2 or less | ||||||

Dust | Less than environment standard | ||||||

Measuring Gas Condition | Temperature | Ambient temperature | |||||

Dust | None | ||||||

Standard gas composition | NO :Up to 5000 ppm | ||||||

Sample inlet tube | Polytetrafluoroethylene tube (6 mm O.D./4 mm I.D.) | ||||||

Sample gas pressure | Atmospheric pressure ± 4 in. W.C. | ||||||

Pressure control | Not including (Vacuum regulator (-9.8 kPa)) | ||||||

Output(Option) | Analog output: 6 channels 4-20mA, 0-1V, 0-5V | ||||||

Calibration gas | Zero gas : Nitrogen | ||||||

| Carrier gas for (Oxygen analyzer | Nitrogen (for N2 carrier specification), Air (for air carrier specification) | ||||||

| Air for ozone generation | Dry air (saturated at ≤ -30°C) | ||||||

Power supply | 100 - 240 VAC (Depends on components) | ||||||

Power frequency | 50/ 60 Hz for common use | ||||||

Power consumption | 240 VA | ||||||

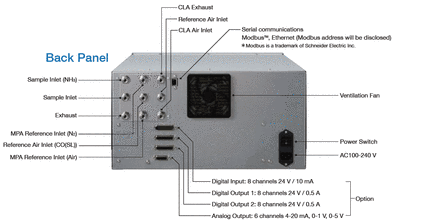

Exterior dimensions/Mass | 5U below in (H)19 in. (W)22 in. (D) / Approx. 19kg (depends on the incorporated components) | ||||||

Materials in contract with sample gas | PTFE, Nylon, PP, FKM, SS304, SS316 | ||||||

| Serial Communications | ModbusTM, Ethernet (Modbus address will be disclosed) *Modbus is a trademark of Schneider Electric Inc. | ||||||

*1: Depends on measurement range specifications.

*2: A range ratio of 1: 40 is also possible for special applications.

*3: A range ratio of CLA NH3 and CLA NOx should be 1: 5 or less.