HyBOPS

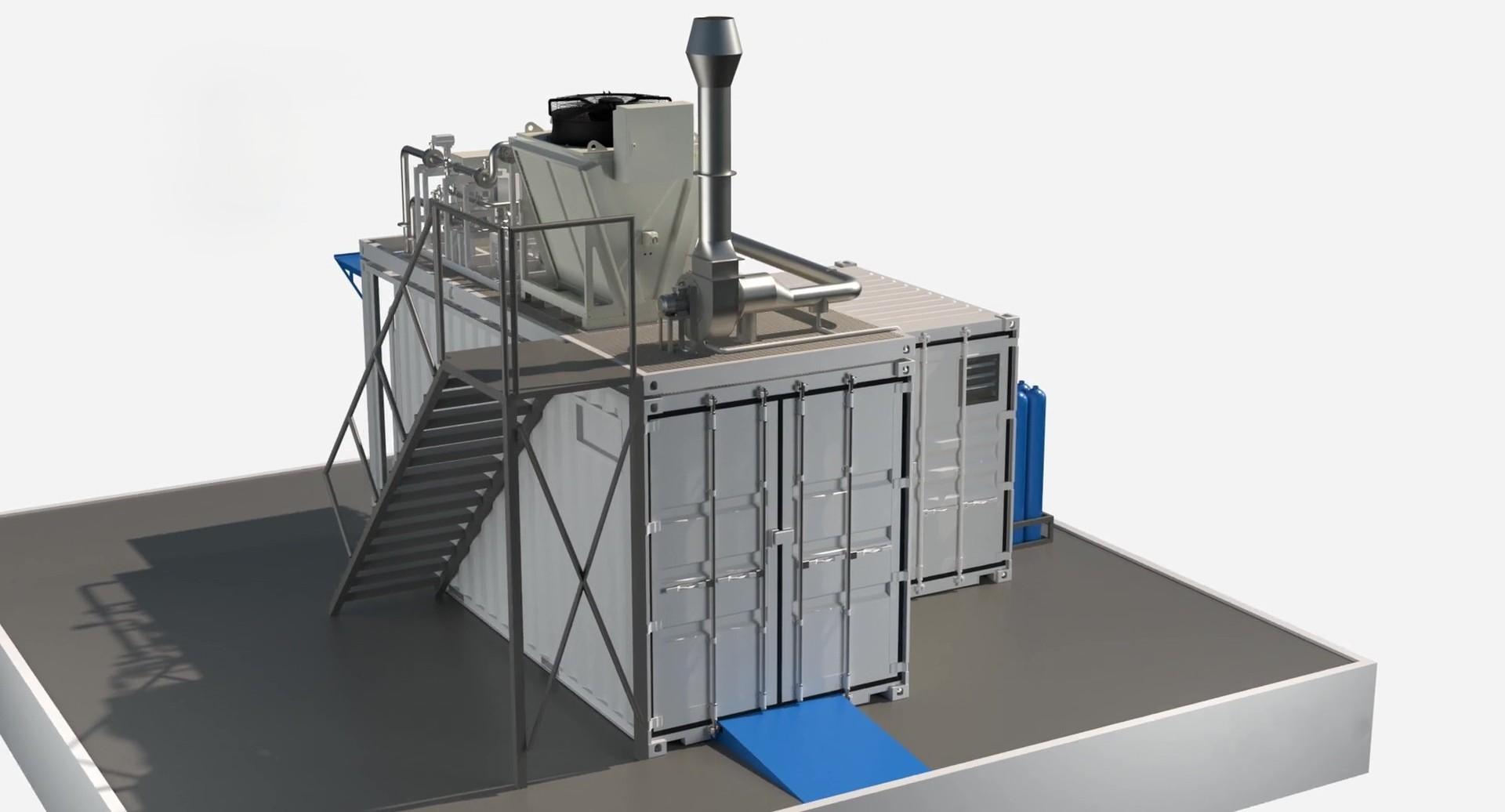

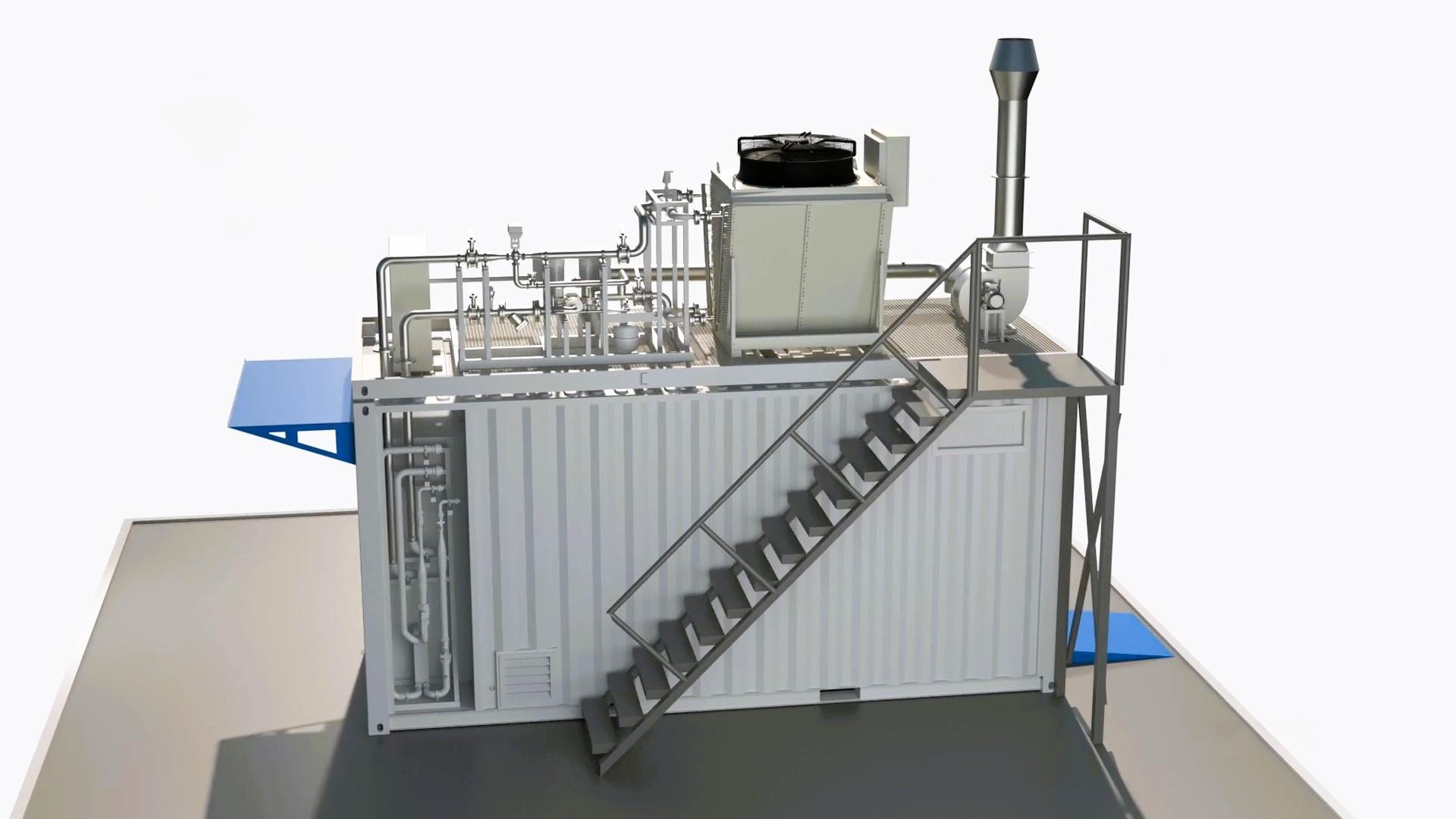

Fuel Cell System Testing Container

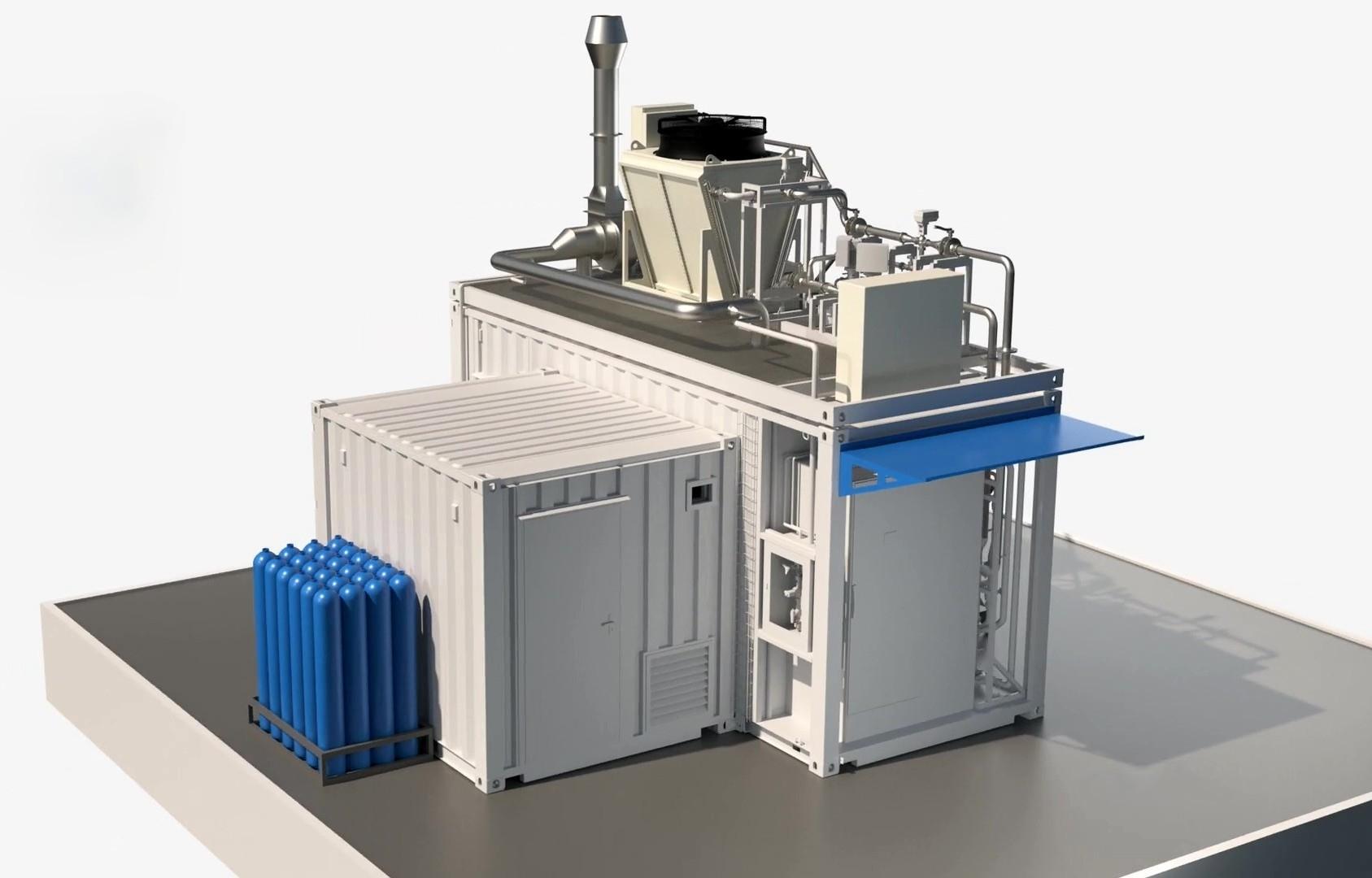

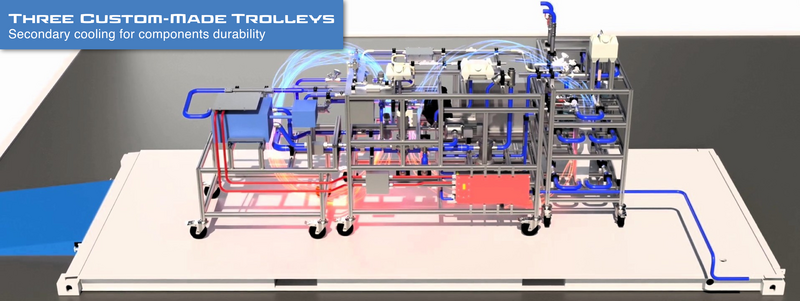

HORIBA delivers a comprehensive hydrogen value chain for fuel cell testing, encompassing every step of the process from material analysis to emissions analysis for fuel cell vehicles. At the core of our solutions is HyBOPS (Hydrogen Balance of Plant System), a fully integrated, turn-key fuel cell testing platform housed within a secure and portable container.

Unlock the Power of Fuel Cell Testing with HORIBA's Complete Hydrogen Value Chain Solutions

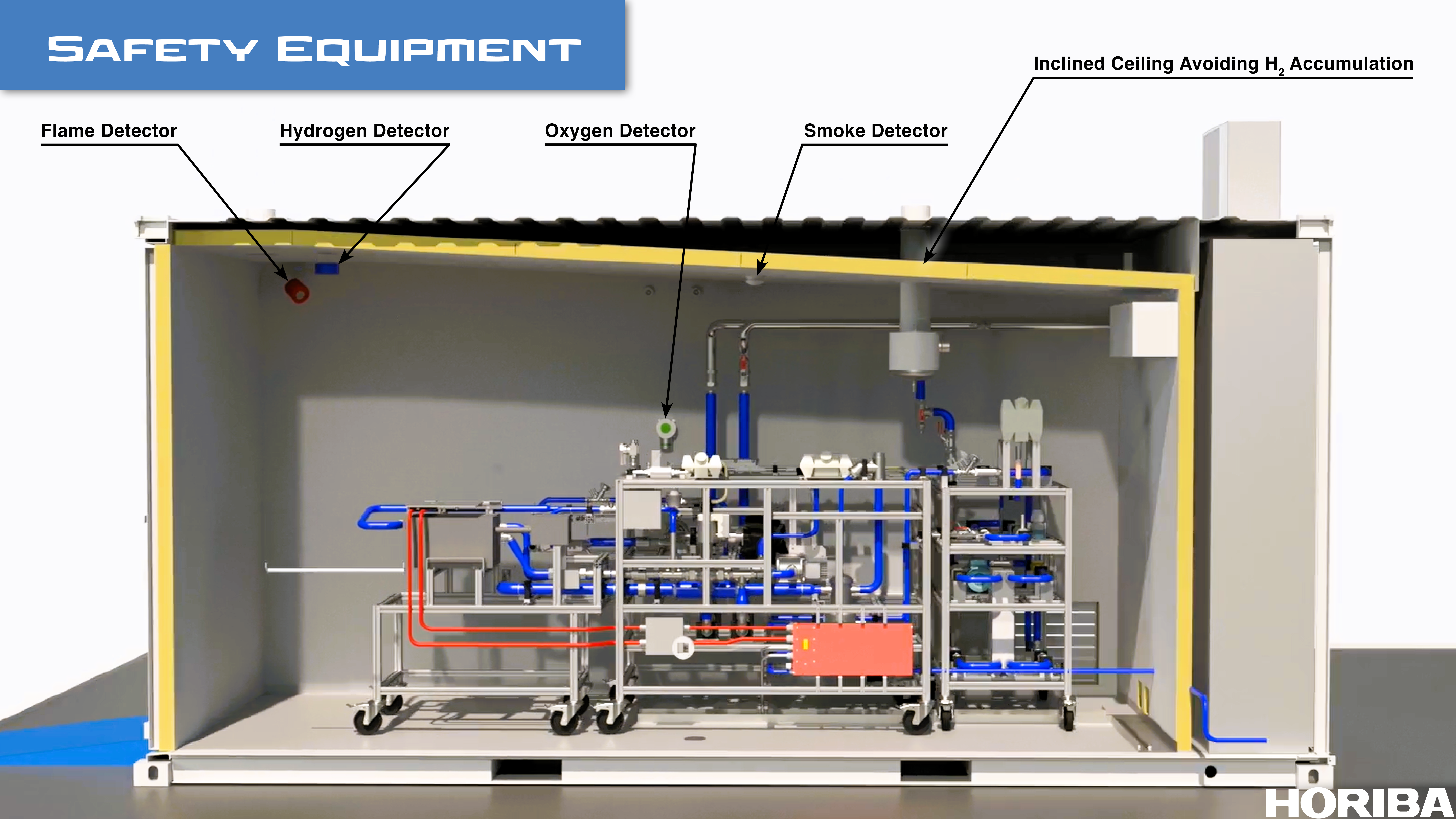

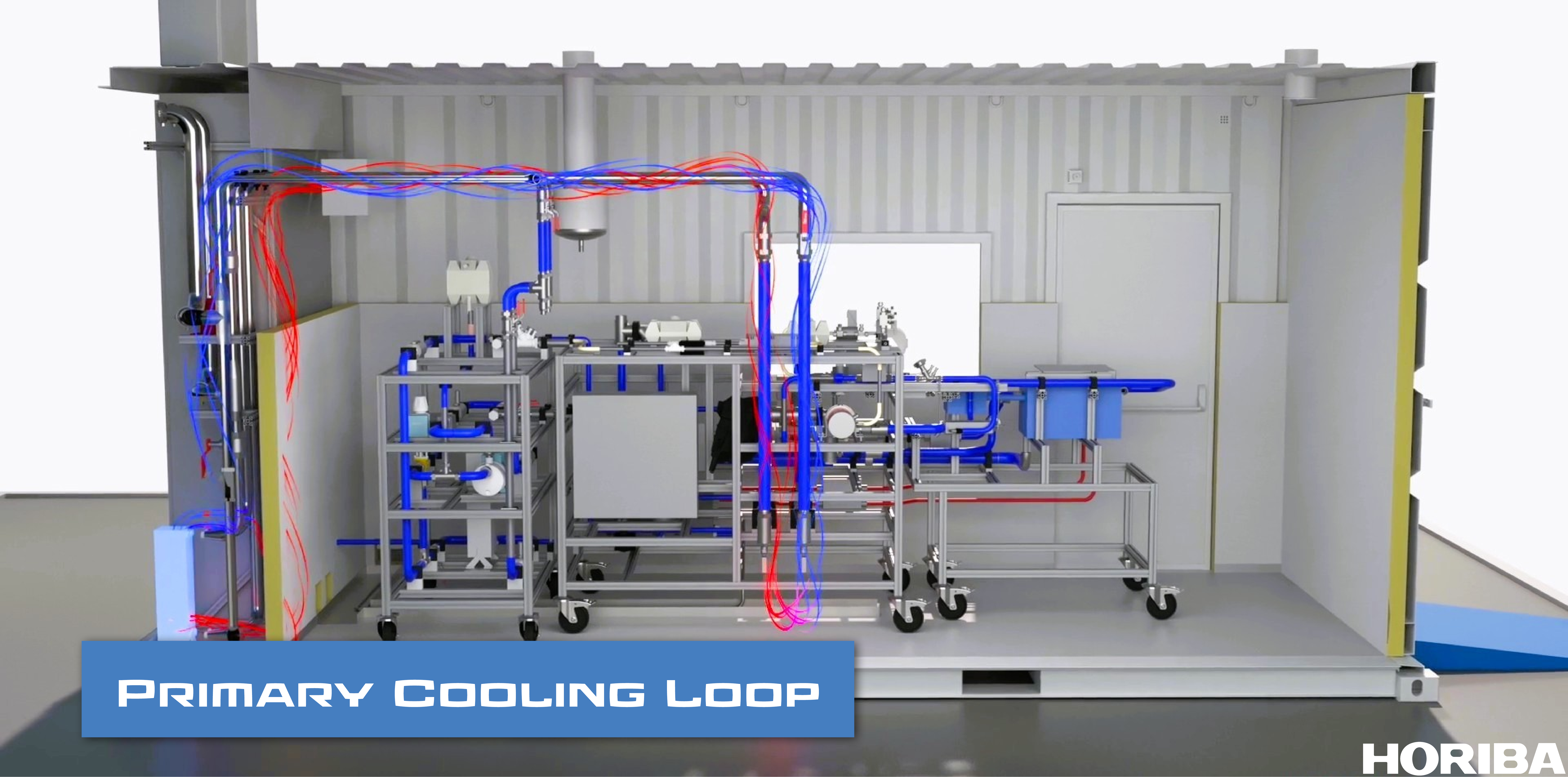

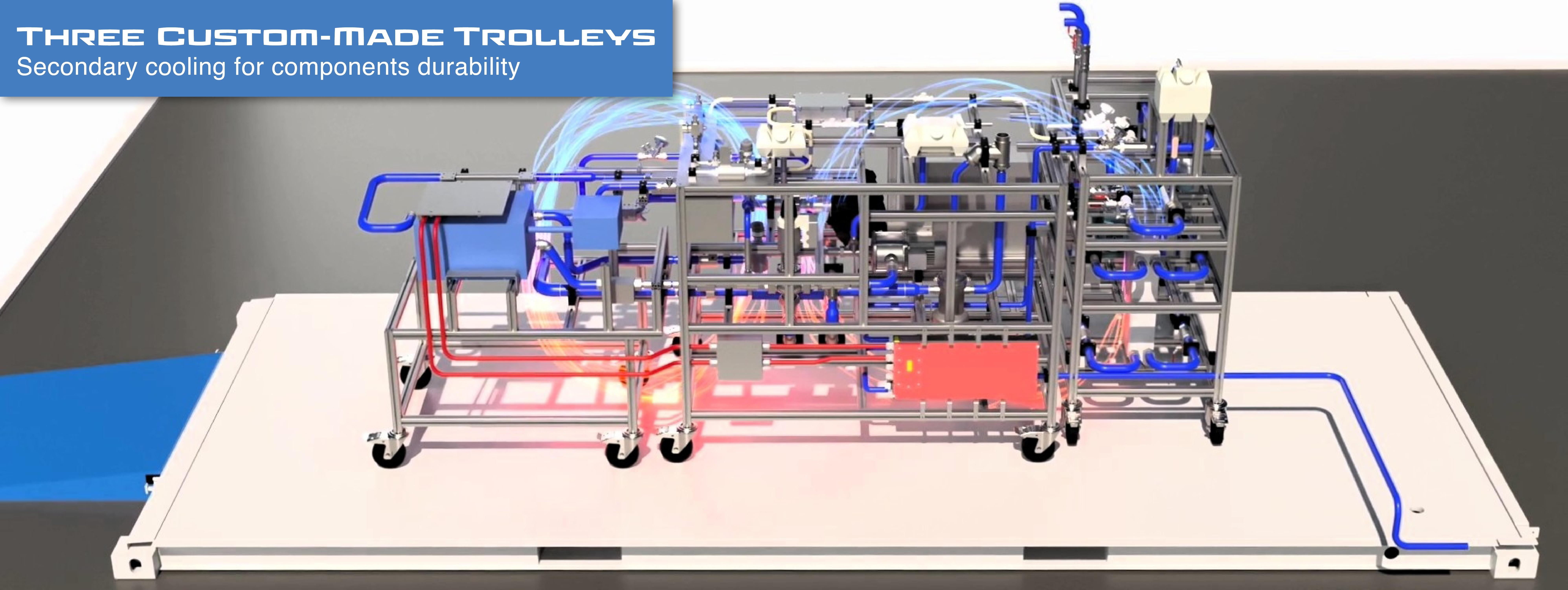

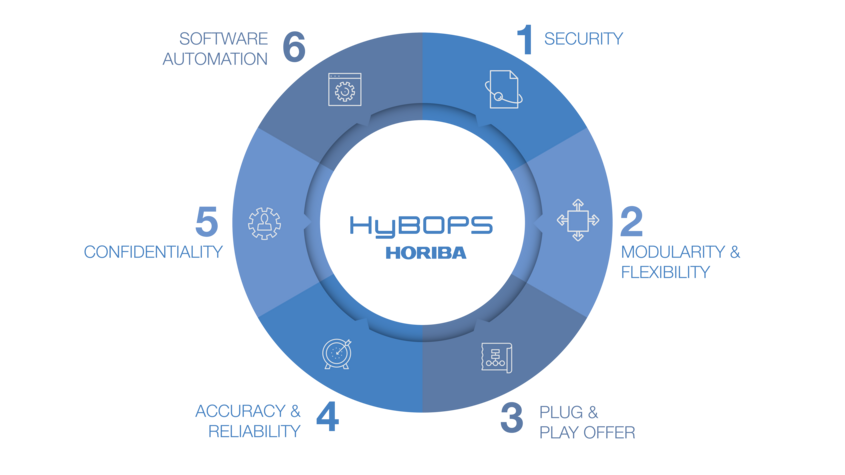

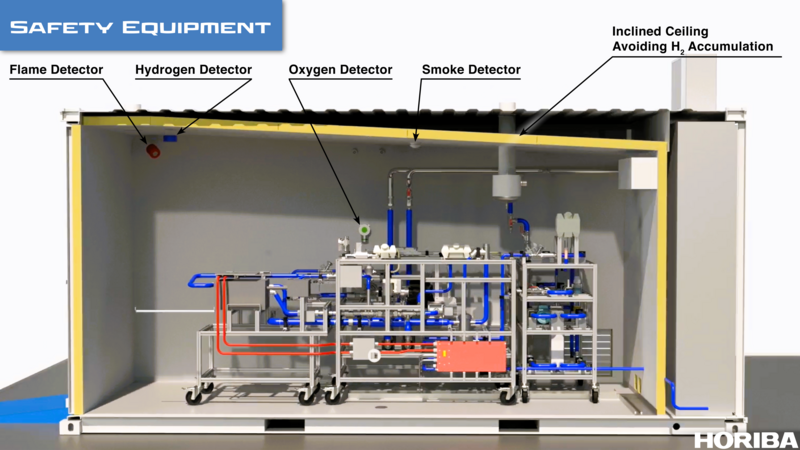

HyBOPS is specifically designed to evaluate fuel cell systems, including hydrogen balance of plant (BoP) components, under real-world operating conditions. This advanced system enables precise analysis to optimize hydrogen BoP components, validate system performance, and refine component selection. By ensuring safety, reliability, and durability through endurance testing, it enhances the development process for fuel cell technologies. Its modular, portable design supports both indoor and outdoor applications, making it a versatile solution that prioritizes operational safety and efficiency.

HyBOPS units, equipped with hydrogen BoP testing capabilities, can be delivered and installed directly at your facility for fuel cell system testing. Alternatively, for urgent testing needs, the HyBOPS testing benches are readily available at HORIBA's Hydrogen Testing Center, where state-of-the-art facilities and expert teams are on hand to test any fuel cell stack or hydrogen BoP system.

Streamline and Save

To streamline testing further, HORIBA offers Test as a Service (TaaS), providing transportable testing containers complete with advanced instruments and expert support. Alternatively, testing can be performed in HORIBA's confidential test centers, which are designed to meet the needs of all stakeholders in the hydrogen and fuel cell industry. Whether on-site or off-site, HORIBA ensures a seamless, efficient, and tailored approach to hydrogen BoP and fuel cell system testing.

HyBOPS Main Features

HyBOPS Main Features

Specifications

Specifications