Greater Accuracy

Proven NDIR Gas Detection Technology

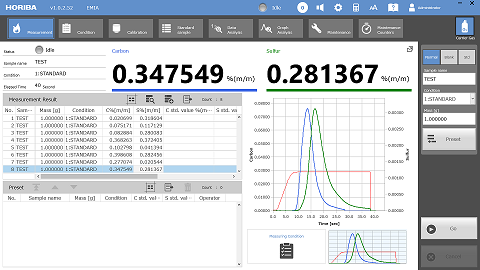

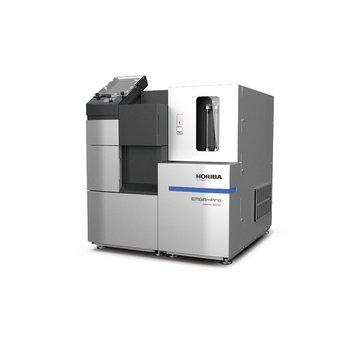

The EMIA-Expert is capable of measuring the concentration of Carbon and Sulfur in samples using the infrared method, which involves combustion in an induction furnace. HORIBA's proven Non-Dispersive Infrared (NDIR) measurement capabilities optimize its range for carbon, from 0.6 ppm to 10.0%, and for sulfur, from 0.6 ppm to 1.0%. The instrument is also equipped with a unique CO detector, and is suitable for a wide range of inorganic materials due to its versatility.

Please also refer the Measurement Principle page for the details.

Standard Accessories for EMIA-Expert

- Purifier Unit for carrier gas (for C Analysis) - Enables measurement of ultra-low carbon concentration with high accuracy by eliminating hydrocarbon impurities in the carrier gas.

- Heating Filter Unit (for S Analysis) - When samples are moist or generate water during analysis, a slight error can occur in sulfur analysis because the evolved water absorbs the SO2 gas. To prevent the absorption of SO2 by moisture and ensure highly accurate sulfur analysis, the heating filter unit can be used.

Improved Measurement and Maintenance Efficiency

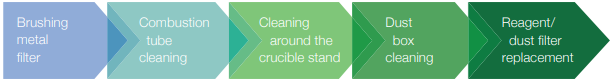

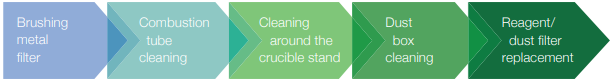

Substantial Reduction in Maintenance

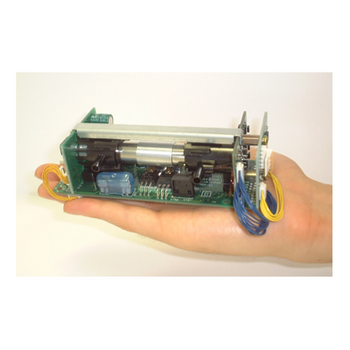

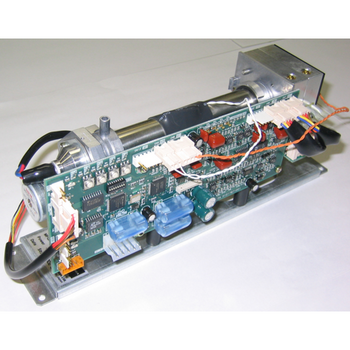

Along with the EMIA-Expert's cleaning feature, HORIBA has developed a robust design with fewer components for more reliable use and less service requirements.

The latest innovations have enabled the cleaning time for the EMIA Series to be typically half that of our conventional models (patent applied for*). Additionally, the structure around the combustion area has been designed to be as simple as possible, allowing for quick and intuitive maintenance. No specialized skills or knowledge required for maintenance work.

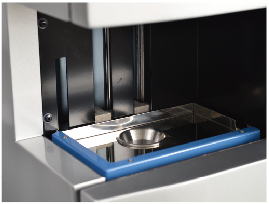

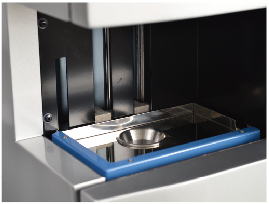

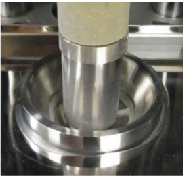

Flat design around the crucible stand

The cleaning efficiency of the EMIA Series instruments has been significantly improved compared to our conventional Carbon/Sulfur analyzers with the use of a unique automatic cleaning mechanism (patent applied for*). This allows users to repeat measurements up to 200 times**, with reduced time required for maintenance and cleaning, without sacrificing measurement accuracy.

* JP6063582, US10379017, EP3064938, ZL201480058824.2, IN351227, JP6605807, US9778148, EP3037814 and ZL201510971175.1

** Number of repeatable measurements may vary depending on the sample and measurement conditions.

Before measurement After 200 measurements

High Throughput

The EMIA Series can complete one measurement cycle, measurement-display result-cleaning, in 70 seconds (i.e. about 50 samples/hour).

Flexible Upgrade after Installation

Customers can expand the functionality of the system at any time, even after installation, to meet their changing needs. Additional options include:

- Auto Sampler Unit - Able to accommodate up to 20 positions.

- Halogen Trap Unit - Helps remove halogen elements in the sample to prevent damage to the device.

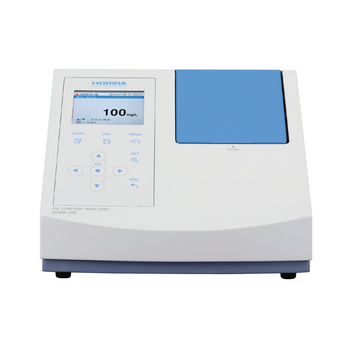

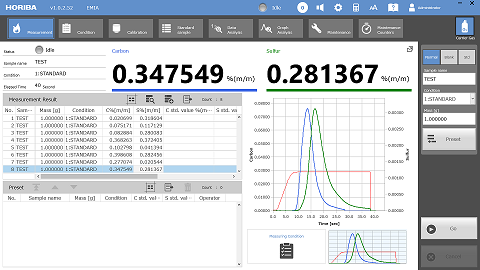

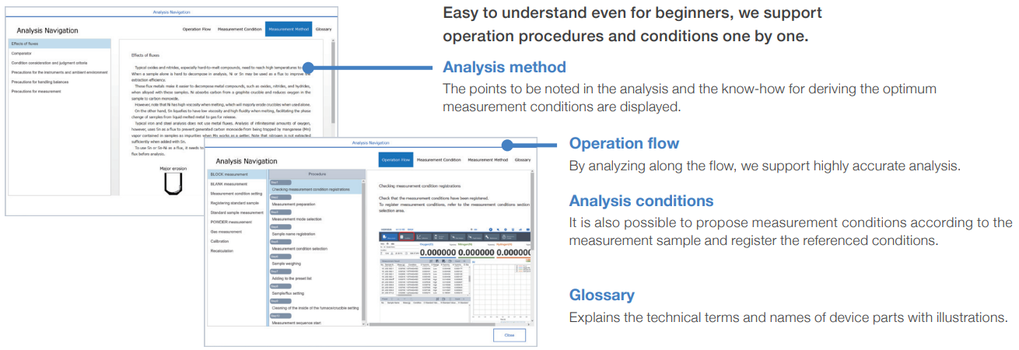

More Intuitive Software for Easy Operation

Advanced Operation Software

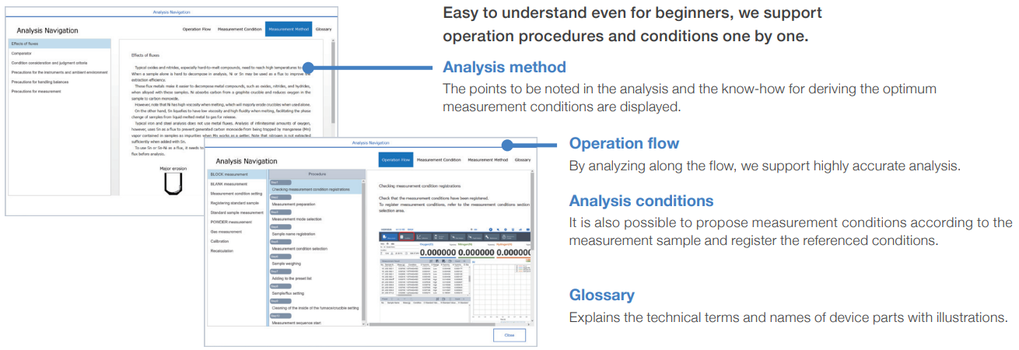

The EMIA Series features its own proprietary operating software, which has been designed with a focus on ease of use, optimizing layout, operating menus, and functions for enhanced user-friendliness.

Enhanced Operator Assistance

Additionally, the software includes a self-diagnostic monitoring feature to assess the status of connected devices, an alarm function, and three navigators to recommend the most suitable conditions for samples, troubleshoot errors, and alert users to perform maintenance. These features improve daily operation and ensure efficient analysis.

*The user interface and functionalities of the software for this system are the same with those of

EMIA-Pro.