By separating and recovering CO2 from various emission gases, then storing and immobilizing it, the amount of CO2 emitted into the atmosphere can be significantly reduced. This is particularly beneficial in combustion processes used in manufacturing and power generation. Additionally, the Direct Air Capture (DAC) technology, which directly removes CO2 from the atmosphere, enables negative emissions. HORIBA supports the research, development and commercialization of these technologies with a wide range of measurement solutions, including gas and liquid measurement, material analysis and evaluation.

Table of Contents

CO2 is separated and captured from exhaust gas generated during the combustion process. This process represents the Carbon Capture (CC component of Carbon Capture, Utilization and Storage). From both cost and technical perspectives, the chemical absorption method is considered advantageous for thermal power plants, the physical adsorption method for chemical plants, and the membrane separation method for cement and steel plants.

Separated and recovered CO2 is also utilized for carbon recycling. Click here for carbon recycling solutions.

To produce high-quality CO2, it is important to measure and monitor CO2 and impurity gases in the separation, capture, and purification processes, as well as in pre and post treatment.

Pretreatment: Sulfur gas contained in the flue gas is removed by desulfurization. SO2 before and after desulfurization and CO2 after desulfurization must be measured and monitored.

Separation, capture, and purification: To optimize the separation and capturing process, it is necessary to control the capture rate of CO2 by amine in the absorption column. Therefore, gas measurement and monitoring of CO2 is important.

Post-processing: By measuring the solution with TOC analyzers after CO2 adsorption and after CO2 separation, the amount of CO2 absorbed, and the amount of CO2 separated can be confirmed. Exhaust gas measurement and monitoring are necessary to ensure that the unwanted gases after CO2 removal are treated and have reached a level that allows final emissions from the stack.

HORIBA Solutions >>

Various measurements and monitoring in the amine method

For concentration monitoring of various gases: Multi-Component Gas Analyzer VA-5000 Series, Stack Gas Analysis System ENDA-5000 Series

For measuring ammonia and amine concentrations: Trace Gas Analyzer APNA-370/CU-2

For simple check of amine solution: pH, Conductivity: Water Quality Analyzer H-1 Series

For detailed condition of amine solution: Process Raman System

For evaluation of CO2 separation and recovery from amine solutions: Automatic Total Organic Carbon (TOC) Analyzer T1 Series

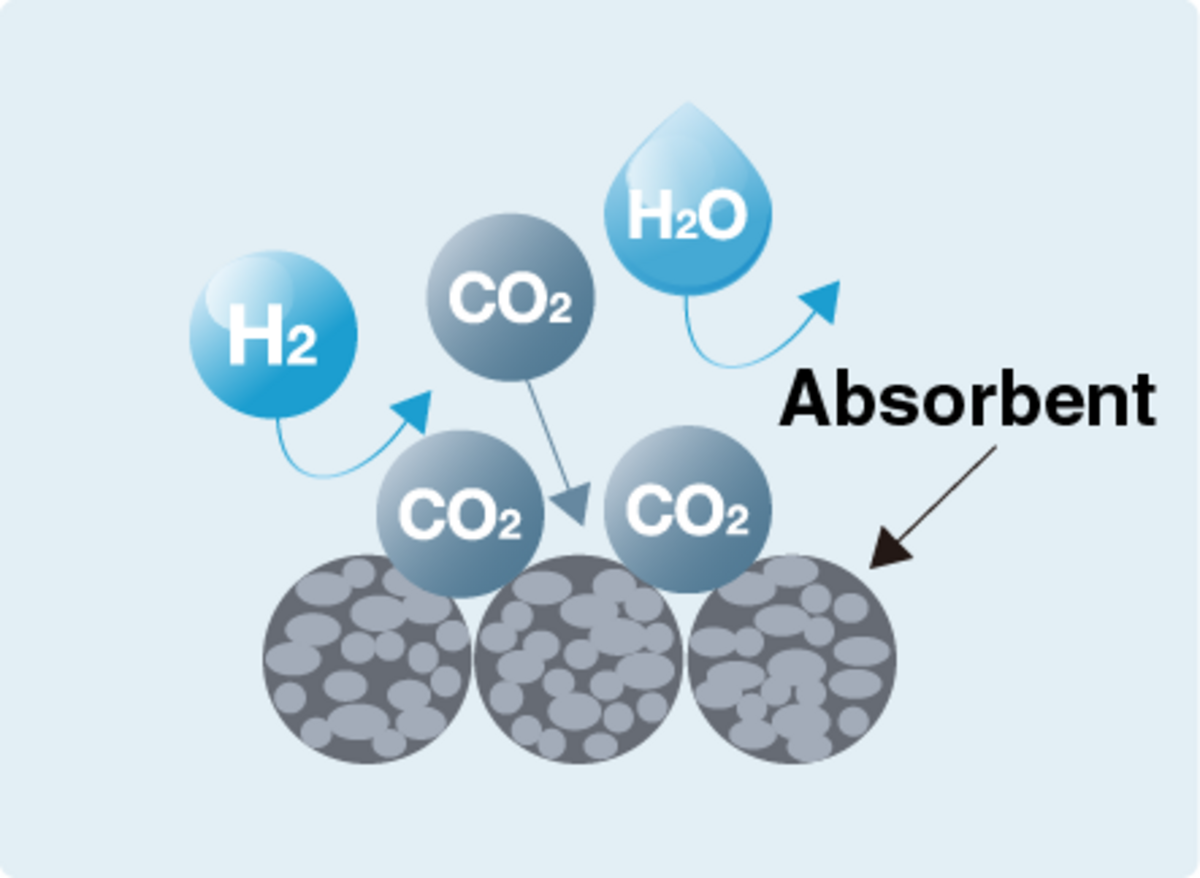

The physical adsorption method is a separation technique in which CO2 is adsorbed onto an adsorbent (porous solid such as activated carbon or zeolite) and CO2 is desorbed by decompression or heating. Using Raman microscopy, which captures the bonding state of substances, and observing state changes such as adsorption that occur on the zeolite surface, this method is useful for performance evaluation and degradation analysis of adsorbents.

HORIBA Solution >>

For Performance Evaluation and Degradation Analysis of Adsorbents: Raman Microscope XploRA PLUS

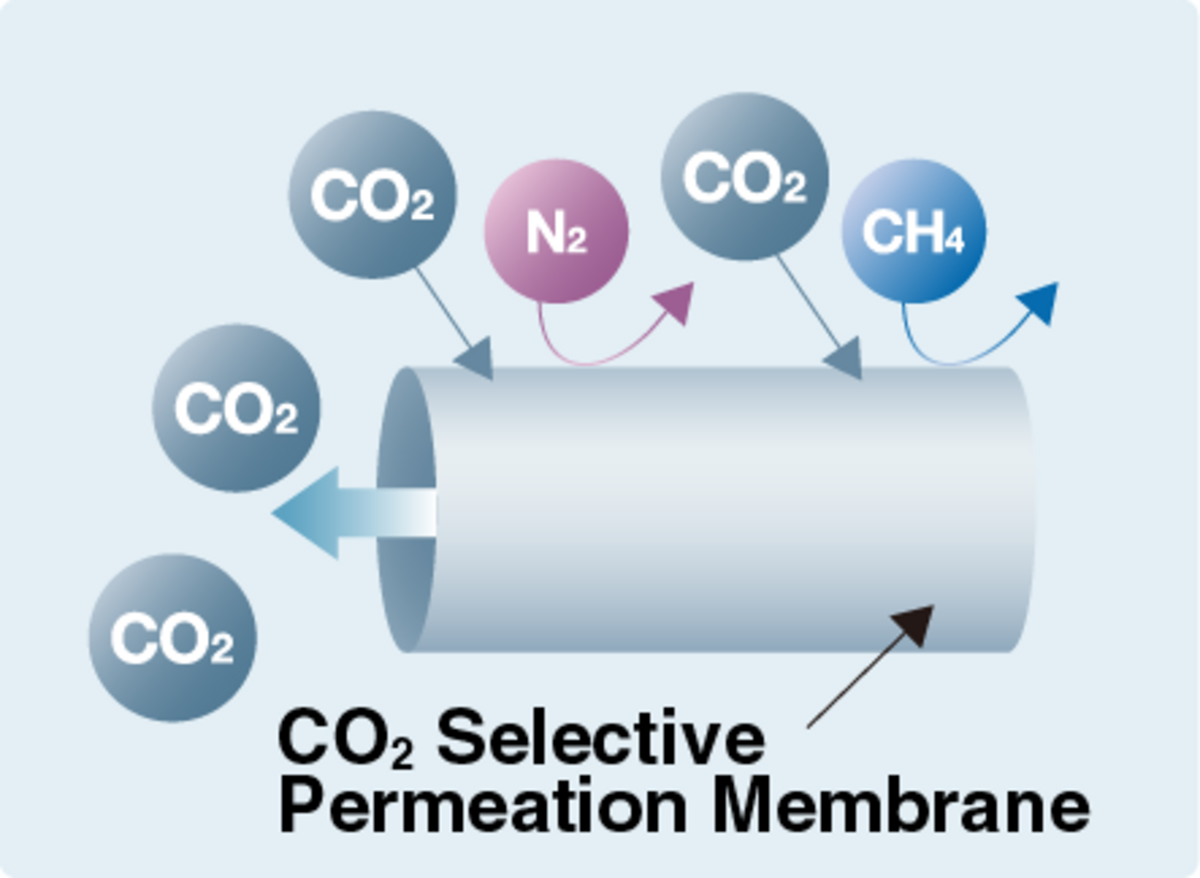

Membrane separation method is a technology to selectively separate CO2 by pressure difference using a polymer membrane with CO2 separation function. By measuring the amount of carbon attached to the separation membrane after the reaction and the amount of sulfur in the catalyst, the degradation of the membrane and catalyst can be evaluated, which is useful for predicting the reaction efficiency and replacement cycle of the membrane.

HORIBA Solution >>

For Evaluation of Membrane Reaction Efficiency and Replacement Period: Carbon and Sulfur Analyzer EMIA-Step

In the hydrogen (gray hydrogen) production process based on coal and natural gas, CO2 generated is separated and captured using the PSA (Pressure Swing Adsorption) method, resulting in the production of hydrogen (blue hydrogen) that does not emit CO2 into the atmosphere. HORIBA contributes to the production of blue hydrogen with solutions developed through its experience in CO2 separation and capture in combustion processes.

HORIBA Solution >>

Direct Air Capture (DAC), which directly captures CO2 from the atmosphere, is attracting attention as one of the technologies to achieve negative emissions*. Large-scale DAC facilities capable of capturing more than 30,000 tons of CO2 per year are now in operation.

*Negative emissions: A technology that achieves negative CO2 emissions by separating and capturing atmospheric CO2 and storing or sequestering it.

While conventional CO2 capture and storage (CCS: Carbon Dioxide Capture and Storage) targets high concentrations of CO2 emitted from thermal power plants, steel mills, etc., DAC separates and captures low concentrations of CO2 in the atmosphere (approximately 400 ppm). Although the target CO2 concentration is different, DAC's CO2 separation and recovery technology itself applies the same chemical absorption, physical adsorption, and membrane separation methods used for conventional CO2 separation and recovery. The technology for storing CO2 recovered by DAC in the same manner as CCS is called DACCS. Future DAC enlargement will require higher performance absorbent, adsorbent, and separation membranes. Another major challenge is to improve the energy efficiency of the entire facility, including energy for the atmospheric capture system.

HORIBA Solution >>

Continuous measurement of atmospheric gas concentrations with the air monitoring system “AQMS” can contribute to DAC R&D and optimization. Furthermore, by combining AQMS with Eco-WEB data management software, which centrally manages data collection, management, visualization, and reporting on a server, a wide variety of data analysis is possible.

HORIBA contributes to the direct capture of CO2 by DAC by combining the engineering of atmospheric monitoring and gas measurement based on solutions cultivated through CO2 separation and capture in various processes and catalyst R&D and quality control solutions.

In the research and development of catalysts and adsorbents, it is important to analyze and evaluate the crystallinity and particle size of the target material, as well as to measure the conversion efficiency of prototype catalyst samples and evaluate their performance quickly and easily. During plant and equipment operation, analyzing and evaluating catalysts and adsorbents in use and controlling their quality leads to improved operating efficiency. HORIBA offers a wide range of analytical, measurement, testing and evaluation solutions for catalysts and adsorbents from R&D to manufacturing.

HORIBA Solution >>

For Evaluation of Catalyst Crystallinity: Micro Raman Spectroscopy Measurement System LabRAM Odyssey

For evaluation of nanoparticle distribution of catalyst materials: nanoPartica SZ-100V2

For measurement of catalyst conversion efficiency: Multi-Component Gas Analyzer VA-5000 Series

For quantitative analysis of carbon and sulfur in catalysts: Carbon and Sulfur Analyzer EMIA-Pro/Expert

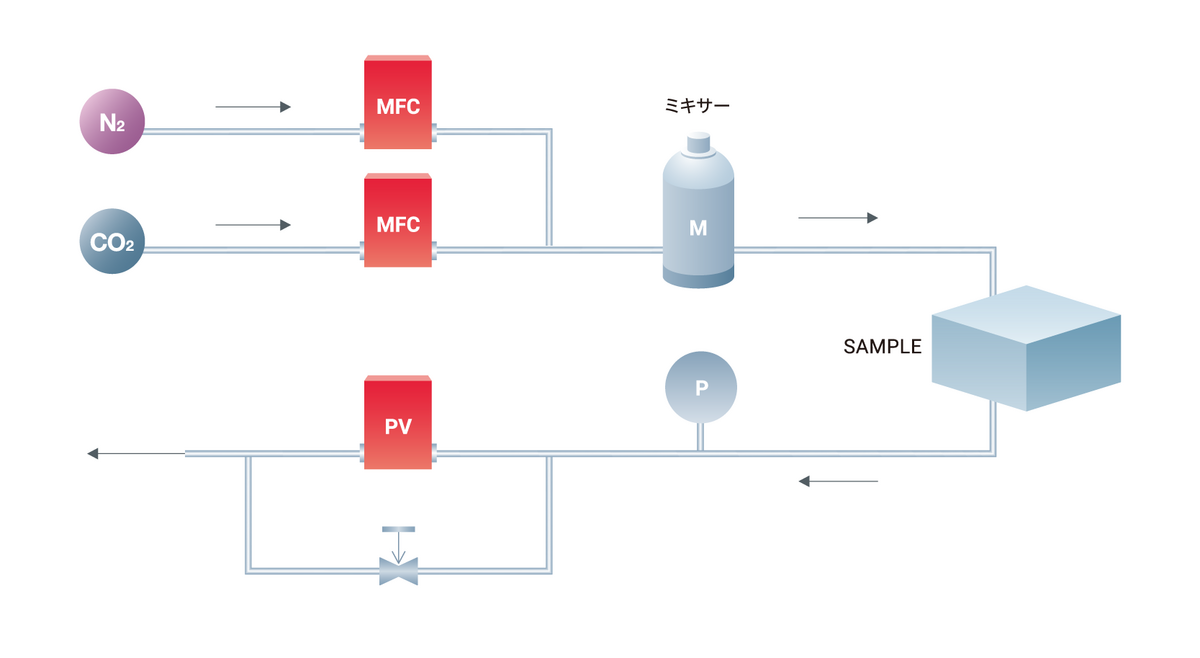

Comprehensive performance and durability testing using a system that combines test equipment that creates a simulated environment close to the various real-world environments in which catalysts and adsorbents are used with optimal analysis and measurement equipment contributes to improved development efficiency and product quality for our customers.

For basic catalyst performance evaluation in R&D: Mass Flow Controller

Captured CO2 is compressed and stored in the ground, oil/gas reservoirs, or sequestered in concrete. This prevents the emission of captured CO2 into the atmosphere.

CCS (Carbon Dioxide Capture and Storage) stably stores the separated and captured CO2 at a high concentration of nearly 100% in a “reservoir” located more than 1,000 m underground.

HORIBA Solution>>

For CO2 Storage Gas Concentration Measurement: Infrared Gas Analyzers for Process Use 51 Series

Since cement, the main raw material of concrete, emits a large amount of CO2 during its production process, efforts to achieve carbon neutrality have begun to combine the reduction of cement usage with the absorption and sequestration of CO2 by concrete.

To reduce the amount of cement used, industrial by-products (coal ash) and special admixtures are used as alternative raw materials to cement during concrete production. The special admixture absorbs and sequesters CO2 that is force-fed to the concrete during curing. The combination of the two is attracting attention for its ability to reduce CO2 emissions from concrete as a whole.

HORIBA Solution >>

Evaluation of CO2 absorption and desorption in concrete

In CO2 adsorption evaluation tests, it is assumed that the amount of CO2 adsorbed in concrete is affected by changes in pressure, so precise control of pressure is required. HORIBA can perform everything from gas supply to the sample to pressure control of exhaust air.

We have a long-standing commitment to analysis and evaluation of advanced materials. Your sample is measured by a highly trained member of our Application Centers and presented as a formal report complete with method, observations, results, and data interpretation assistance.

In addition to consultation on the selection of analytical instruments, we also provide analytical technologies through services such as contract analysis and joint research with customers and academia, utilizing our know-how and skills as an analytical instrument manufacturer.

Do you have any questions or requests? Use this form to contact our specialists.