Greater Accuracy

Proven NDIR Gas Detection Technology

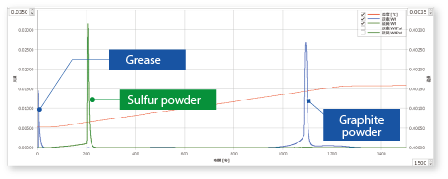

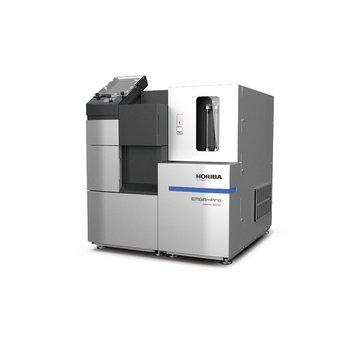

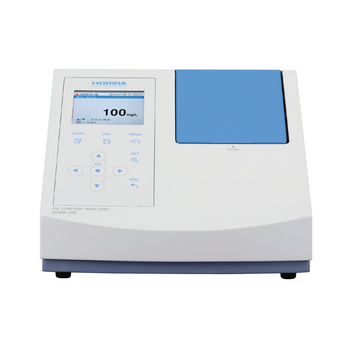

The EMIA-Step Carbon/Sulfur Analyzer uses the infrared method to measure Carbon and Sulfur after combustion in an electric resistance furnace. With HORIBA's renowned Non-Dispersive Infrared (NDIR) measurement capabilities, it can detect carbon ranging from 0.0003 to 6.0% (m/m) and sulfur ranging from 0.0004 to 1.0% (m/m). The analyzer is also equipped with a unique CO detector and can be used for a wide range of inorganic materials, including steel, cokes, catalysts, non-ferrous alloys like aluminum, and lithium-ion battery materials.

Please also refer the Measurement Principle page for the details.

Temperature Control Function

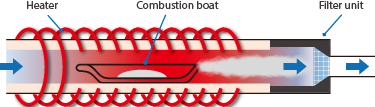

The combustion furnace of the analyzer utilizes a distinctive sealed system, which facilitates efficient combustion of flame-retardant samples through high-pressure oxygenation. The system offers excellent temperature stability, ensuring consistent performance across low and high temperatures. This broadens the range of applications to samples containing substances that are easily decomposed and burned at low temperatures. The decomposition combustion of organic and inorganic matter can be easily observed.

Temperature rise control from 300 °C to 900 °C

Improved Measurement and Maintenance Efficiency

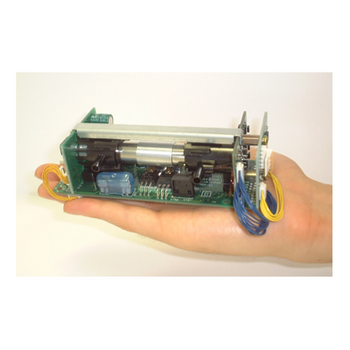

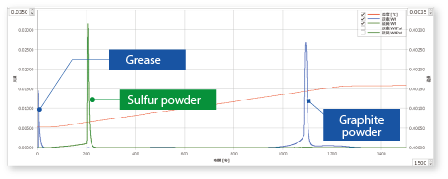

New dust-filter provides easy maintenance capability

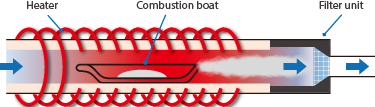

The EMIA-Step features a dust-filter mechanism that has been proven effective in high frequency induction heating models. The filter unit collects dust generated by high-temperature combustion to prevent it from adhering to the piping after the combustion furnace. This reduces the adsorption of CO2 and SO2 gases by dust and ensures highly accurate and sensitive analyses.

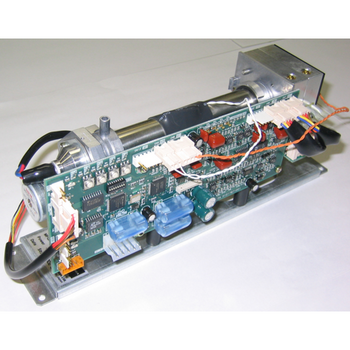

Schematic of tubular electric resistance heating furnace

High Throughput

The EMIA Series can complete one measurement cycle, measurement-display result-cleaning, in 70 seconds (i.e. about 50 samples/hour).

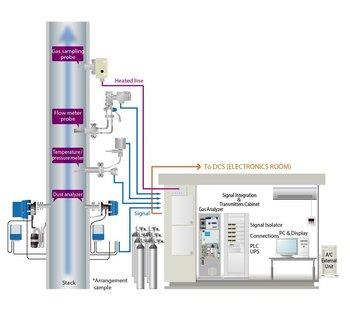

Gas Collection Mode

Our exclusive furnace features a closed structure that enables efficient combustion under high-pressure oxygen and allows for the burning of high melting point materials. This unique furnace design allows Gas Collection analysis, in which small amounts of gases are captured within the furnace and then transferred to the detector for analysis.

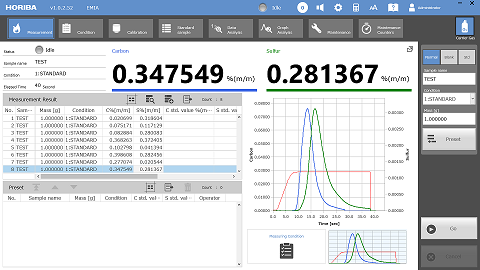

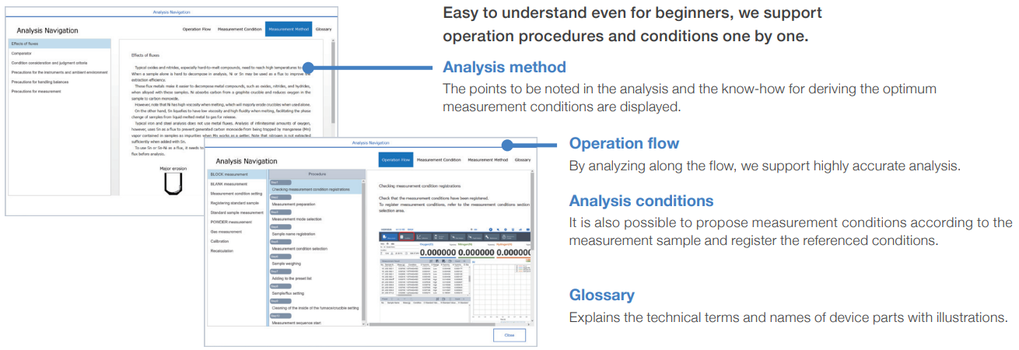

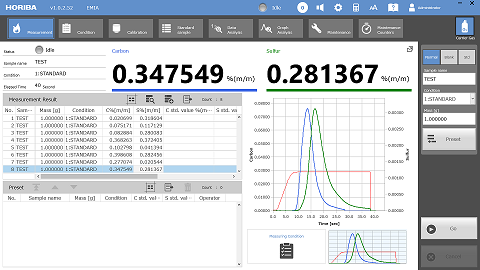

More Intuitive Software for Easy Operation

Advanced Operation Software

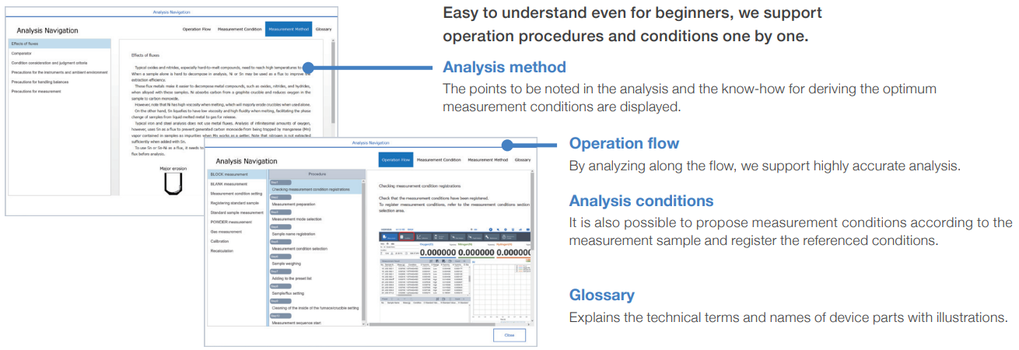

The EMIA Series features its own proprietary operating software, which has been designed with a focus on ease of use, optimizing layout, operating menus, and functions for enhanced user-friendliness.

Enhanced Operator Assistance

Additionally, the software includes a self-diagnostic monitoring feature to assess the status of connected devices, an alarm function, and three navigators to recommend the most suitable conditions for samples, troubleshoot errors, and alert users to perform maintenance. These features improve daily operation and ensure efficient analysis.

*The user interface and functionalities of the software for this system are the same with those of

EMIA-Pro

Compliance with ISO/ASTM Standards