- Monitoring of Total Hydrocarbon, Non-Methane Hydrocarbon and Methane Emission in RTO inlet and RTO outlet -

Volatile organic compounds (later, VOCs) are organic compounds which are easily evaporate under normal atmospheric conditions of temperature and pressure. These VOC compounds are produced and emitted as gases from different industries and during different production process i.e. the manufacturing of the paints, pharmaceuticals, semiconductors etc.

VOCs have adverse health effects and its emission into the atmosphere is often regulated by the government environmental authorities or companies’ self-management and CSR initiatives. Therefore, industries are obliged to control and mitigate VOCs emission, and there are many alternative technologies such as regenerative thermal oxidation, catalytic oxidation, adsorption by activated carbon, and others to reduce VOCs emission from industrial stacks.

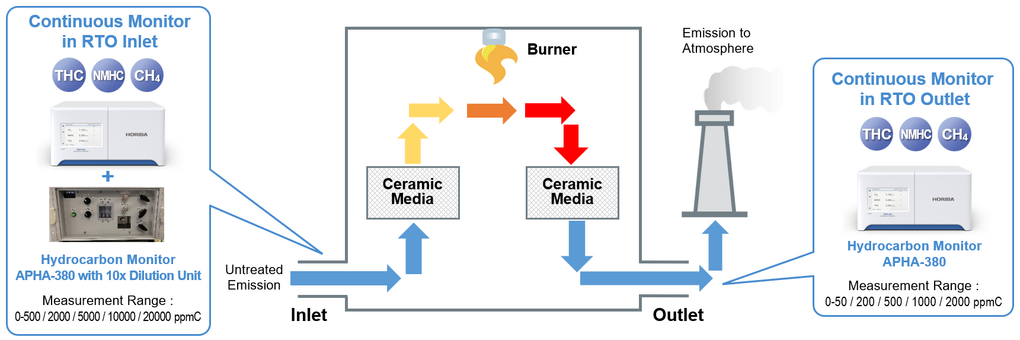

The Regenerative Thermal Oxidation (later, RTO) method is commonly used due to various reasons such as cost efficiency, efficient heat recovery, installation environment etc. The treatment is realized in following steps: 1) Untreated emission containing VOCs is sent through the ceramic regenerator column, where it is preheated. 2) Preheated gas enters combustion chamber, where the temperature is raised up to approx. 800°C by fire burner. This heating up process is the trigger for oxidation reaction of VOCs and its decomposition into H2O and CO2. 3) Treated gas is cooled down by passing through another ceramic column, which absorbs heat and recovers it for the next cycle of heating. Cooled down and clean gas is exhausted into the atmosphere.

Analyzers for monitoring of VOC/THC are often installed at the RTO inlet and outlet for several purposes. The first purpose is detection of abnormal efficiency of RTO, control and optimization of treatment process. The second purpose is monitoring for self-management and voluntary reduction effort by companies. The third purpose is regulatory monitoring for controlling VOC emission below defined by environmental regulations limit value and complying with environmental regulation.

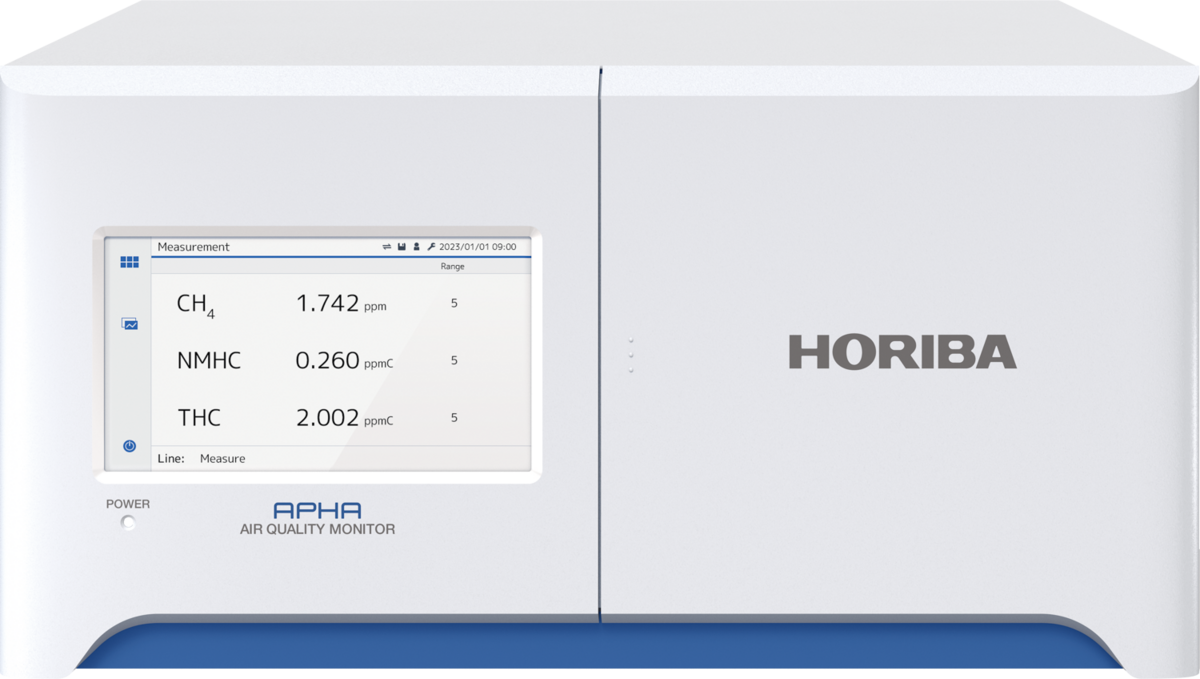

The APHA-370 monitor is successfully utilized for the RTO inlet and outlet monitoring, which helps customers to control RTO efficiency and final VOC (Non-Methane Hydrocarbon) and THC emission concentration.