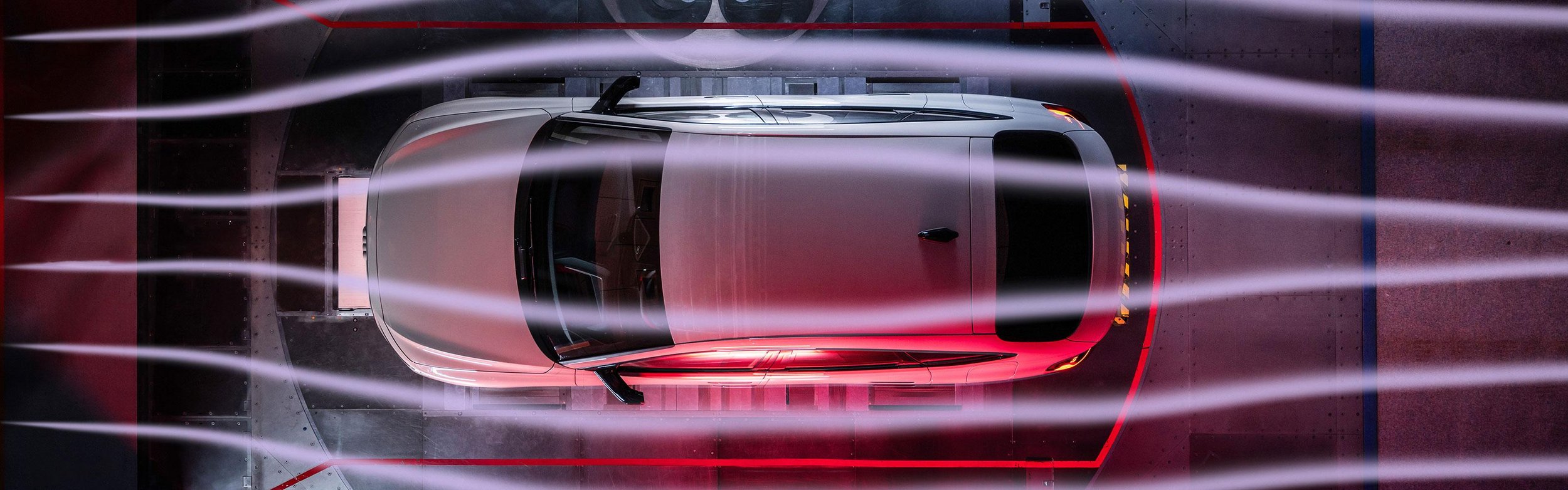

For more than 50 years, HORIBA has been a leading global supplier of wind tunnel balance systems. We are among the few companies worldwide specializing in the design and construction of aerodynamic balances with moving ground simulation systems, offering fully integrated solutions tailored for the mobility sectors.

Whether you're building a new wind tunnel or upgrading an existing facility, our custom solutions are designed to meet your specific needs, from road vehicles and aircraft to components of buildings, trains and ships.

Our six-component wind tunnel balance system enables precise measurement of drag, side force, lift force, rolling moment, pitch moment, and yawing moment.

Leverage our decades of experience and first-class service to maximize the performance of your wind tunnel balance from the start.

Increase productivity and runtime | |

Easy Maintenance | |

Worldwide Service |

Do you have any questions or requests? Use this form to contact our specialists.