Spectroscopic Charge Coupled Device (CCD) detection systems are available with a wide range of sensors and cooling options. The purpose of this document is to help you to select the most appropriate options for your application. Virtually all spectroscopy between 200 nm and 1100 nm is performed using a silicon-based multichannel detector and a spectrograph. Multichannel detection has enabled spectroscopy to be used in research and analytical applications that previously were not possible with single channel scanning spectroscopy, offering both better signalto-noise performance and acquisition speed.

Linear photodiode arrays (PDAs) and CCDs offer low-cost, high-speed data acquisition for a wide range of applications. Two dimensional CCDs offer the added advantages of variable detection area size and the ability to monitor multiple sources simultaneously. They are typically more sensitive and are used in high-end research and multipoint analysis industrial applications.

CCD detection systems specifically designed for spectroscopy are sometimes referred to as cameras. However, they incorporate CCD sensors which typically have larger pixels and are longer than the CCDs used for imaging applications. Imaging CCDs typically are 6 mm x 4 mm with pixels smaller than 10 μm square. Spectroscopic CCDs are often 25 mm or longer and have pixels around 25 μm square. They also do not have masking for image transfer. CCD cameras for spectroscopy are cooled to reduce dark noise.

The priorities for spectroscopic acquisition are different than for image acquisition. In imaging, spatial resolution is more important than dynamic range. In spectroscopy, spatial resolution is not as critical as horizontal spatial resolution, which is mapped to spectral resolution, and is determined by the spectrograph. In most imaging applications the dynamic range, i.e. the ability to differentiate shades of gray, usually does not have to exceed 1,000 to 1. In spectroscopy, higher dynamic range is important for making measurements over a wide range of intensities. A typical scientific CCD detector has an intrinsic dynamic range of over 300,000 to 1. All spectroscopic CCD systems have 16 bit analog to digital

converters (ADC) limiting the measurable dynamic range to 65,535 to 1 or less.

The main goal of a spectrometric measurement system is to be able to distinguish the spectral features from the noise, within the time limits imposed by the phenomenon, and environmental or financial factors. In light-starved applications, the collection optics, spectrograph options, and CCD detector configuration are all critical.

Approximate signal to noise ratios.

All spectra have noise. It is important to ensure that the signal from the sample exceeds the sum of the noise components. The signal-to-noise ratio (SNR) must be greater than 1/1 to distinguish a spectral feature from the noise. A peak with a SNR of 4/1 may not look pretty but none-the-less, is unambiguous and may be acceptable for qualitative analysis. Higher SNRs are usually required for quantitative analysis.

There are many sources of noise that will affect the quality of a spectrum. The source itself has some instability, the spectrometer has some level of stray light, and the table may vibrate. Here, however, the discussion will be limited to noise sources associated with the detection system.

The SNR can be the ultimate consideration in applications where the flux is very low during the allowable measurement period. The limitations can be due to an intrinsically low signal, temporal variations in the sample structure, or source duration. In most other cases, i.e., if time permits, the SNR can be improved by integrating longer. The increase in the SNR will be the square root of the factor increase in the integration time. Increasing the integration time from 2 seconds to 4 seconds will increase the SNR by a factor of 1.414. Thus doubling the integration time of a spectrum with a SNR of 4/1 will increase the SNR to 5.6/1.

CCDs are available with a wide range of sensor and cooling options. Understanding the experimental constraints and the noise associated with the component choices can make the difference between getting any spectra and paying too much to get them. Fig. 45 shows spectral features with approximate SNRs indicated above each.

The following discussion will help you to understand how each CCD camera noise source contributes to the total noise, and which ones are insignificant or dominant when selecting the right detector options for your application.

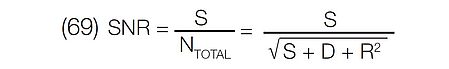

The basic equation for determining the SNR for a CCD detector is shown below where:

S = signal being measured

N = total noise

D = dark signal

R = readout noise.

Shot noise, also referred to as quantum noise, is caused by the statistical variation in the counting of the number of photons and cannot be eliminated.

Shot noise, also referred to as quantum noise, is caused by the statistical variation in the counting of the number of photons and cannot be eliminated.

This variation follows a classical Poisson distribution and can be described as the square root of the number of detected photons in the

measurement period. The statistical variation for a 100 photon measurement would be between 95 and 105 photons. The SNR of this measurement would be 100/√100 = 10/1.

Shot noise is almost always the dominant detector noise source in experiments employing cooled CCD-based detection systems once the signal rises above any background signal.

Thermionic or dark noise.

Just as photons can free electrons, thermal vibrations within the sensor can do the same. The number of freed electrons for any given temperature and acquisition period is very reproducible. With uncooled or minimally cooled detectors the dark current can often be higher than the signal being measured. Taking a dark measurement for the same integration time as the measurement and subtracting it from the measurement is a common practice. There is however, an analogous shot noise component in the dark current.

The colder the sensor, the lower the dark current and its associated noise. A liquid nitrogen (LN ) cooled CCD has a dark current in the fractions of electrons per pixel hour range, and for all practical purposes, does not have a dark noise component. Scientific grade CCD detection systems built with Peltier thermoelectric coolers (TE) typically reach temperatures below 200 K. These CCDs have noise components in the fractions of electrons per second, which for most applications, is more than adequate. However, for extremely weak phenomena requiring integration times in the minutes range, a LN cooled detector may be a more appropriate choice.

Readout noise is due to uncertainty in the reading process. t is usually specified as some number of electrons RMS. RMS, Root Mean Squared, is a statistical measurement and the actual number of electrons read out for any pixel could vary over an approximate peak to peak range of 5 times the RMS value.

Readout noise is due to uncertainty in the reading process. Readout noise is usually specified as some number of electrons RMS. RMS, Root Mean Squared, is a statistical measurement and the actual number of electrons read out for any pixel could vary over an approximate peak to peak range of 5 times the RMS value. A difference of a few electrons in readout noise has no discernible effect on the overall SNR in even the most difficult applications. Readout noise is measured in total darkness with the minimal attainable integration time. A signal of only 25 photoelectrons in a measurement period would have a shot noise above the readout noise of most scientific grade CCD detectors.

Fig. 48 shows the readout noise from two arrays. While statistically a 1 electron difference is detectable for any single repeated measurement, there are over 1000 pixels being read out in a spectrum. For any given pixel, the device with the higher RMS readout noise may in fact have lower noise. When the shot noise from the signal is superimposed over this, there is no possibility of making a measurable distinction.

If the readout noise is above the shot noise for a 10 minute exposure, there is a good chance that a usable spectrum may not be acquired.

Cosmic rays are ever present. When one strikes a CCD sensor it may cause electrons to be freed along its path. Some of those will be captured and add to the noise. The average hit rate is 5 events/cm /minute. For most applications, cosmic rays are not a factor, as the signal is usually stronger and the integration time short. For extremely weak phenomena however, where the signal may be in the 10s of photons per second range, and integration times approach 20 to 30 minutes, cosmic ray-induced noise can render a spectrum unreadable. Most spectroscopic software has a cosmic ray removal algorithm. In essence, two spectra are taken and any feature not found in both spectra is subtracted. However,

cosmic rays cross columns and rows, and even with the algorithm, long exposure spectra can be distorted beyond analytical validity. See Fig. 49, If the readout noise is above the shot noise for a 10 minute exposure, there is a good chance that a usable spectrum may not be acquired.

QE indicates what percentage of the photons that strike the sensor will ultimately result in an electron being captured and read.

There are several options to consider when selecting a sensor. Quantum efficiency (QE) is often considered the most important. The QE indicates what percentage of the photons that strike the sensor will ultimately result in an electron being captured and read. A standard front illuminated sensor has virtually no sensitivity below 400 nm and would be inappropriate for UV measurements. In figure 50, the front illuminated open electrode (OE) sensor has approximately 50% QE at 550 nm. The front illuminated sensor with a UV coating (FIUV) has approximately 25% QE at the same wavelength. This indicates that for the same incident flux, the OE sensor produces twice as many detectable electrons. Thus for the same integration time the OE sensor will have a SNR 1.414 (√2) times better than the FIUV sensor, or an equivalent SNR ratio could be attained in half the time.

At approximately 320 nm, the back illuminated UV sensor (BIUV) has a QE of 60%, the OE 35%, and FIUV 15%. The BIUV can acquire equivalent data in 0.6 the time of an OE (35/60) or with a SNR gain of 1.31 (√(60/35) over the OE. Comparing the BIUV to the FIUV yields either a four times speed advantage or a two times SNR advantage. Fig. 51 shows the SNR comparisons at extremely low light levels. For applications where a SNR of 10/1 or better is routinely achieved, these small differences may not be worth the cost. In deciding between a back illuminated CCD and a front illuminated version, it is the relative difference in QE that matters, given conditions that are not shot noise or time limited. A back illuminated sensor is most appropriate for weak, one-shot kinetic or reaction-time limited measurements in the sub-second range or in cases where the necessary integration times are very long and there is potential for cosmic ray effects.

The relative differences in QE in the visible and NIR are at best 50% between a front illuminated and back illuminated CCD. This corresponds to the difference in SNR between the red and green spectra. In the UV however, the relative difference can be over four times, corresponding to the difference between the red and violet spectra.

The 50% difference between a 40% and 60% QE for example, will yield a SNR gain of 1.25, corresponding to the difference between the red and green spectra in Fig. 51. The highest relative difference in the VIS and NIR is only about two times. This yields a SNR improvement of 1.4 which corresponds to the difference between the red and blue or blue and violet spectra. In the UV however, there is a significant difference between a front illuminated (UV coated) and a back illuminated sensor; as high as five times the QE.

This produces a difference that is close to a comparison between the red and violet spectra.

Purchasing a sensor with the highest QE does not always guarantee a meaningful improvement in spectral quality. It almost always however, adds to the cost.

The FWC of a sensor is specified in thousand electrons, ke-, and indicates the total number of electrons that can be measured in a readout register pixel. The pixels in the readout register are usually slightly larger than the others.

The FWC of a sensor is specified in thousand electrons, ke-, and indicates the total number of electrons that can be measured in a readout register pixel. The pixels in the readout register are usually slightly larger than the others. As electrons are transferred down the columns to the readout register pixel, the FWC is also the maximum for any column. In most low light level applications this is not an issue. In applications where the light is relatively intense or where the measurement can be made over a time scale that permits maximizing of the signal, it can be important. A larger FWC permits the measurement of more intense signals. It may also permit a higher dynamic range in the measurement, i.e. it can distinguish smaller peaks in a spectrum with a full scale peak than a sensor with a smaller FWC depending on the electrons per count setting.

Schematics of each type of sensor are shown below with brief bullet points describing each sensor’s advantages and disadvantages.

Pixel size has been associated with better spectral resolution. A 20 μm wide pixel will have a smaller number of wavelengths falling on it than a 26 μm wide pixel. The only applications where this difference in size may have an effect are those with extremely narrow atomic emission spectra taken with long focal length, low aperture spectrographs. For all other applications, selecting a spectrograph and grating combination that has a higher resolution than required for the measurement is more important.

Most molecular spectra, Raman and fluorescence for example, have relatively broad features and can be measured with spectrographs between 0.3 m and 0.6 m. The off-axis aberrations in these are greater than the 6 μm difference in pixel width, over much of the focal plane. Further, it is very rare, especially in low light applications that a slit width below 25 μm would be appropriate. A higher grating density or longer focal length spectrograph would permit the use of a wider entrance slit for equivalent resolution, and more importantly, would capture more light. The slit width is the determining factor in resolution. If the slit width is greater than the pixel width, the pixel will not have any effect on resolution. There would be no advantage in having a smaller pixel, however there would be a FWC reduction as the small the pixel the fewer electrons it can hold.

Sensors are cooled to reduce the dark current level and its associated noise. Spectroscopic CCD systems are available with either thermoelectric (TE) cooling or liquid nitrogen (LN ) cooling. Manufacturers claim TE cooling levels between -80 C and -100 C (with optional power supplies and water circulation). At -80 C most CCDs have a dark current of about 0.002 electrons per pixel per second. The dark current for any readout is the combined dark current from all of the pixels readout in any column. For a 256 pixel high sensor, with all pixels in a column being read, the total dark current would be (0.002e/pixel) x 256 pixels or 0.5 electrons per second. To obtain a dark noise level just equivalent to a 3 electron readout noise would require about 18 seconds. Clearly, for even fairly long acquisition times cooling is not a concern, and is never an issue in even extremely weak experiments in sub-second time scales.

Etaloning is a phenomena that can interfere with some spectroscopy measurements, but may have no interference for other measurements.

With a back illuminated sensor, the incident light strikes the photosensitive silicon layer directly. The silicon layer is physically thinned leading to higher quantum efficiency, but also causing etalon fringe effects from reflections between the silicon and silicon dioxide layers.

Etaloning is a phenomena that can interfere with some spectroscopy measurements, but may have no interference for other measurements. To limit etaloning and increase quantum efficiency, a thicker substrate may be applied to BI sensors. This type of sensor is referred to as back illuminated deep depletion.

The discussion so far has considered photons and electrons. Photons from the sample release electrons in the sensor. Those electrons, the electrons in the dark current, and the electrons produced by the readout process are combined in the measurement. The values shown on the screen however are counts. There are 65,535 counts discernable with a 16 bit analog to digital converter. The electronics permit the user to define how many electrons make up one count by means of adjusting the amplifier gain. HORIBA Scientific’s electronics permit a gain selection of between 1 and 8 electrons per count. The ability to choose the gain is important in optimizing the SNR and the dynamic range.

In extremely low light levels, where the readout noise is in the same order of magnitude as the shot noise (with a gain of 1 electron per count) it is theoretically possible to eventually distinguish the signal from the noise, assuming there is enough time to integrate before external forces affect the data. With a readout noise of 3 electrons, it would only take less than 25 signal electrons to overcome the readout noise, making the measurement shot noise limited.

At this level however, the maximum measurable intensity would be 65535 electrons, as that is the limit of the ADC. Furthermore, the dynamic range would be limited to 65,535/3 or 21,845 to 1.

Using a gain of 4 electrons per count, at signal levels just above 25 electrons, would reduce the readout noise to one count. In fact, it would reduce any readout noise less than 6 electrons to one count (which covers most scientific CCD detectors). Thus, over 260,000 electrons could be measured before saturation and the dynamic range would be higher, 65,535 to 1.

A gain of 4 electrons per count is the optimum gain for covering both extremely weak and very strong signals with the highest possible dynamic range. At this gain any readout noise between 1 and 6 electrons would be indistinguishable as they would nearly always fall within first count.

Fig. 55 shows the conversion pathway from photon to count.

A gain of 4 electrons per count is the optimum gain for covering both extremely weak and very strong signals with the highest possible dynamic range. At this gain any readout noise between 1 and 6 electrons would be indistinguishable as they would nearly always fall within first count.

A gain of 4 electrons per count is the optimum gain for covering both extremely weak and very strong signals with the highest possible dynamic range. At this gain any readout noise between 1 and 6 electrons would be indistinguishable as they would nearly always fall within first count.

Fig. 56 shows a comparison of a spectrum taken with gain settings of 1 and 4 electrons per count (e/ct). When displayed on the same scale, the 4 e/ct looks cleaner. This is due to the fact the readout noise is reduced to 1 count while it is 3 counts at the 1 e/ct gain setting.

When the 4 e/ct peak is expanded to the same height, as the other as shown on the right, we can see that the noise level appears slightly higher. At this signal level it is two times higher. The difference is due to the shot noise difference in the signal intensities, the readout noise being just a few percent of the total noise.

Above 21,845 counts the 4 e/ct setting would have a better SNR and would be sensitive signal levels above the 65,535 counts imposed by the 1 e/ct gain.

A clock rate of 100 MHz does not permit twice as many spectra to be taken as with a 50 MHz clock rate. Further, the spectral rate is highly dependent of the size and location of the area of the chip being read out.

Scientific CCDs must be in the dark while the signal is being transferred as there are no masks to prevent photons that strike outside the measurement period from contributing to the measurement. Generally, for non-intensified CCDs, an electromechanical shutter is required. These shutters can run reliably for exposures as short as 50 ms, allowing about 20 spectra per second to be acquired.

It is possible for the user to place a mask in the optical path that only allows a portion of the sensor to be illuminated. This may allow higher spectral rates. These rates are highly dependent upon the height of the sensor and the size and location of the measurement area on the sensor. For shorter exposure times, an intensified CCD (ICCD) is required as it can admit and block light in the nanosecond time scale. For reaction times faster than a few nanoseconds, a path length differential between the excitation and measurement signal allows data to be taken using pulsed lasers and nonintensified CCD detection systems.

In all cases, whether intensified or not, the data from the pixels must be shifted down the columns and then across the last row to be measured. The time to shift the rows down and out is a significant portion of the time it takes to read out a spectrum. The clocking rate refers only to the number of pixels per second that pass through the ADC. See Fig. 57, A clock rate of 100 MHz does not permit twice as many spectra to be taken as with a 50 MHz clock rate. Further, the spectral rate is highly dependent of the size and location of the area of the chip being read out. Unfortunately, there are no standards for the procedure used in calculating spectral rate. Some manufactures consider reading out only one row for determining the maximum spectral rate, while others consider the results of shifting all of the pixel data down and out.

Most manufacturers provide a choice of clocking rates between 20 kHz and 1 MHz. If a spectrum is taken with a shutter, the maximum number of spectra is not clock rate limited. There is an intrinsic advantage in using the lowest clocking rate possible. Slow clocking rates produce lower readout noise and allow the ADC to count with higher precision. The measure of this precision is called the charge transfer efficiency. The differences can be nearly imperceptible, but possibly may show up in exceedingly low light.

The above discussion provides a good deal of guidance for the user who has some prior knowledge about the acquisition conditions and signal to noise ratios that will be encountered with the experiment. There is however, a large percentage of users who do not know what to expect. For those, we offer the following three rules which should be applied even before the system specification begins.

Rule Number One

Do a literature search. Find published spectra of experiments or procedures that are similar to what you plan to do. Look at the SNR of the spectra. Look at the equipment used and the acquisition time. If your source is half as intense, and the sample concentration is 10 times lower, your SNR will be √20 times lower for the same integration time.

Rule Number Two

If published spectra have, or your anticipated data has a SNR less than 10/1, definitely contact an applications scientist from the equipment vendor who is familiar with your area of investigation. Rule Number Three Do not use a back illuminated CCD if you are making measurements above 750 nm (except when the back illuminated chip has anti-etaloning technology). A phenomenon called etaloning will cause the longer wavelengths to reflect back from the rear surface and produce interference patterns.

An Electron Multiplying CCD (EMCCD) uses the latest technology to enhance the signal to noise (S/N) ratio in measurements where extremely low signal levels are present.

An Electron Multiplying CCD (EMCCD) uses the latest technology to enhance the signal to noise (S/N) ratio in measurements where extremely low signal levels are present. In low light regimes the electron multiplication process can provide a good S/N ratio, unlike the conventional CCD where only a few of the stronger features can be just observed above the noise.

The benefits of EM gain are clearly obvious in fast Raman imaging, where the necessary short integration times can often result in signals which are barely visible above the noise when measured with a conventional CCD.

An Electron Multiplying CCD (EMCCD) uses the latest technology to enhance the signal to noise (S/N) ratio in measurements where extremely low signal levels are present.

The EMCCD has two readout registers on the chip – a conventional register and an EM register. In the EM register, the clocking voltages used are higher than for conventional clocking, causing the electrons to acquire sufficient energy that impact ionization can occur. At this point, extra electrons are produced and stored in the next pixel. There is only a small probability of electrons acquiring sufficient energy for impact ionisation to occur (thus creating additional electrons) but since the readout register has many elements within it, significant gain factors are possible (up to ~1000x).

The key benefit of an EMCCD is that the amplification occurs before readout of the signal, which means that the signal is not readout noise limited. In other words, through amplification the signal is raised well above the noise floor which is largely determined by the noise of the readout electronics (preamplifier and A/D convertor).

CCD Selection Guide Based on Application and Exposure.

The suggestions below are based upon working with thousands of researchers in a wide gamut of physical, chemical, and biological applications. As they are rules of thumb, they may not be exactly right for your particular application. Talk with an applications scientist. HORIBA Scientific’s application scientists have thousands of hours of experience in making spectroscopic measurements, and although they may not fully understand the nature of your research, they fully understand the characteristics and limitations of the optics and detection systems.

Use back illuminated sensors and LN cooling for:

UV anything:

Analytical anything:

Fig. 60 shows the relative intensities and time scales for a wide range of applications. As stated above, this also is a generalization.

This paper so far has focused exclusively on CCD detection systems. Although they are frequently the most expensive component in a spectroscopic system, incremental improvements in spectral quality can be more profoundly affected by proper selection of other components in the system. Factors of two gain in SNR are not possible, except in the UV, by selecting a different sensor. However, factors or two of more can easily be gained or lost based upon how efficiently the input optics collect the signal and how well it is coupled to the spectrometer. Changing the focal length of the spectrometer or doubling the grating groove density (going from 1200 to 2400 gr/mm) can in many applications, increase throughput by factors of two without a resolution penalty.

To get the highest performance for your financial investment you must take all components in the optical train into account. An investment of a few hundred dollars in optics may yield a higher benefit than a several thousand dollar investment in a better sensor.

HORIBA Scientific has been manufacturing both CCD detection systems and spectrometers longer than any other supplier. It has the largest and most experienced staff of optical and application scientists specializing in spectroscopy. Your requirements are evaluated from a systems perspective, without prejudice towards any one component.

Do you have any questions or requests? Use this form to contact our specialists.