Many food products exist in particulate form ranging from powders to emulsions, suspensions and pellets. The size distribution of the particulates can affect the taste, appearance, stability, processability, and functionality of the final product.

Proper particle characterization of food products requires a range of analytical instrumentation. All of the HORIBA particle technologies have been successfully applied into the food industry including laser diffraction, dynamic light scattering and image analysis. Specific applications of particle size analysis in the food industry have been documented in the sections below.

Coffee needs to be ground after roasting either at a central facility or closer to the point of consumption. The level of size reduction depends on several factors including the brewing method and desired flavor. Control of the particle size prior to brewing is critical but the measurement can be challenging depending on the instrument used. The HORIBA LA-960V2 Partica has the dynamic range required to analyze the entire distribution and the automatic control of the PowderJet dry powder accessory needed to make robust, easy measurements.

Chocolate is a mixture of milk solids, cocoa powder and fats. Particle size of cocoa powder used in chocolate affects color and flavor strength. The industry refers to “mouth feel” as a gauge of acceptability or rejection. If the particles are too large, it will not have a consistent creamy taste. Particle size also affects the level of bitterness when tasted.

Mayonnaise is one of the most popular condiments world-wide and is prepared in many different ways. Determining particle size during formulation and manufacturing are important factors to ensure the acceptance of new, healthier mayonnaise.

Milk is an emulsion that is homogenized to reduce the average particle size, which improve its consistency and extends shelf life. The homogenization process is expensive and careful control of the process can improve quality and consistency and reduce operating costs.

Quality control is an essential part of the sugar production. Traditionally, sugar manufacturers have chosen to use sieving analysis due to its low initial cost and its seemingly simple operating procedure. In this study, the LA-960V2’s ability to rapidly analyze particle separation and the particle size of powdered sugar at its de-agglomerated state is demonstrated.

Flavor emulsions are used in many food products including carbonated beverages and dairy products. A typical flavor emulsion contains essential oils, emulsifiers, and stabilizers in an aqueous continuous phase. The particle size of the emulsions droplet is critical for stability. Given the sub-micron size range of most flavor emulsions, the size analysis can be performed with either laser diffraction or dynamic light scattering (DLS).

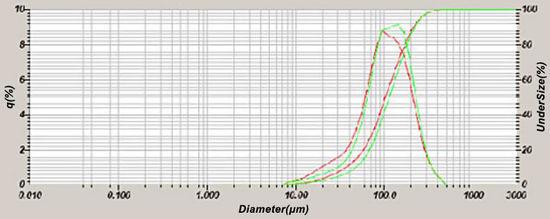

Flour is the product of milled grains. Typically the distribution is wide and the size varies depending on the desired final product. Flour particles have a tendency to swell when run wet. The solution is to use ethanol and a sequence program to automate the process as much as possible. When flours are run dry they will closely match wet data without the threat of the particles swelling. The wet vs. dry comparison shown below plots results from the same sample using these two different approaches on the LA-960V2 Partica system.

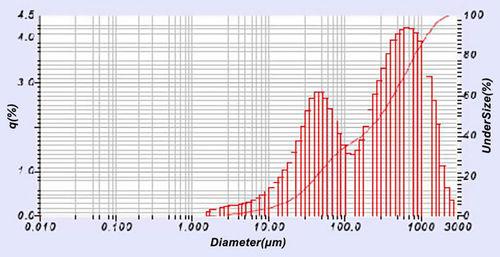

Bean paste is a milled bean product containing large sections of the seed coat along with varying sizes of ground cotyledons, the fleshy section of the bean. Particle size of these components has a direct effect on mouth feel, flavor, and consistency of the final product. To ensure a consistent product, a company should have some procedure to monitor and control size from batch to batch and facility to facility.

Pinto bean paste was measured on the Partica LA-960V2 system using the following test conditions:

RI (particle): 1.50-0.10i

Dispersant fluid: De-ionized water with no surfactant

Sonication: None

Circulation speed: 3

Agitation speed: 4

Notes: Let circulate for 30 seconds to mix and stabilize before taking measurements.

Discussion: To verify the LA-960 results, this sample was wet sieved at 1700 microns. The sample weight retained on the sieve was 3.1g from a 100g sample. The measured result on the LA-960 was 3.7% above 1700 microns, confirming the excellent performance of the instrument at larger sizes.

Laser Scattering Particle Size Distribution Analyzer

Simultaneous Multi-Laser Nanoparticle Tracking Analysis (NTA)

Laser Scattering Particle Size Distribution Analyzer

Nanoparticle Analyzer

Do you have any questions or requests? Use this form to contact our specialists.