The impact of flavoring or flavorants can be summed up by using a single letter a few times: “Mmmm”.

Foods we love rely on flavorings (or flavorants) to enhance their taste. These can range from simple salt and sugar to fruit extracts and complex mixtures of spices. Flavorants can reduce the costs of food processing while allowing a healthier diet. For maximum impact, particle size is important. Chefs and food scientists look beyond the name of the flavor and consider how it behaves during cooking and manufacturing. Much of this depends on particle size.

Like many materials, the material properties important in processing depend on particle size. The flow or water absorption during mixing and blending depends on particle size. Results of volumetric measurements (such as with a cup or when feeding with an auger) will depend on particle size since the bulk density of the material depends on particle size and shape.

Is "quick dispersion" valuable? Once again, particle size plays a role. Particle surface area since affects the speed of a dispersion or dissolution process. And particle surface area is a strong function of particle size. Particle size can be rapidly determined with the LA-960V2 Particle Size Analyzer.

Some flavorants should be obvious to the consumer, such as large granules of sugar on top of a muffin or blueberries within that muffin. However, other flavors, such as the vanilla should be invisible. Bluntly put, the eyes taste before the tongue or nose. Whether the product has expected uniformity and color is vital to customer acceptance. Since the eye has a finite resolution limit for visible particles and even smaller particles have scattering effects that affect product appearance, particle size is important to assuring optimal customer acceptance.

These eggs would not look so tempting without the splash of color. The spice powder must be big enough to see.

Emulsion droplets with a wide size distribution will grow due to Ostwald ripening. Overly large particles will rise to the top or fall to the bottom of a suspension. This is important even for emulsions that are further processed. For example, it has been found that smaller emulsion particle sizes lead to more stable emulsions resulting in a better quality encapsulated product after spray drying.

For all of these issues, careful particle size distribution measurements can provide answers to vexing stability problems.

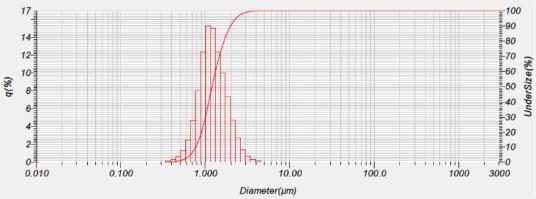

LA-960 data from flavor emulsion. The LA-960 can be used to determine width of the emulsion size distribution.

The behavior of particles in the mouth affect the texture and mouth feel of the final flavoring product. Larger particles lead to an inconsistent taste, that is less creaminess. Large particles also lead to grittiness. Interestingly, extremely large particles do not affect perceptions of texture and mouth feel.

Flavor is also affected by particle size. For example, smaller salt particles will dissolve more quickly and lead to a stronger flavor effect even as the total amount of sodium is decreased. Smaller particle sizes also enhances the perception of fat content.

Like with stability, particle size information can help address issues of texture, mouth feel, and flavor.

Soup ingredients are important to final mouth feel.

Laser Scattering Particle Size Distribution Analyzer

Dynamic Image Analysis

Direct Imaging Particle Analyzer

Nanoparticle Analyzer

Centrifugal Nanoparticle Analyzer

Laser Scattering Particle Size Distribution Analyzer

Laser Scattering Particle Size Distribution Analyzer

BET Flowing Gas Surface Area Analyzers

BET Surface Area Analyzers

Simultaneous Multi-Laser Nanoparticle Tracking Analysis (NTA)