HORIBA Scientific Pulsed RF Glow Discharge Spectrometers are used in universities where they contribute to the development of new materials with coatings at nano-scale and upward and in industries to monitor photovoltaic devices manufacturing, to understand the origin of corrosion on painted car bodies, to assess the composition of precious metals, to control hard disks or LED manufacturing, to improve Li batteries, etc.

Cross collaboration with the advanced plasma coating research community has helped to drastically improve the instrumentation in the last 15 years, ISO standards have been published and the technique is now well established for material characterisation.

Pulsed RF GDOES is the ideal tool to investigate from the surface down to more than 150 microns with a depth resolution that can be as good as 1 nm.

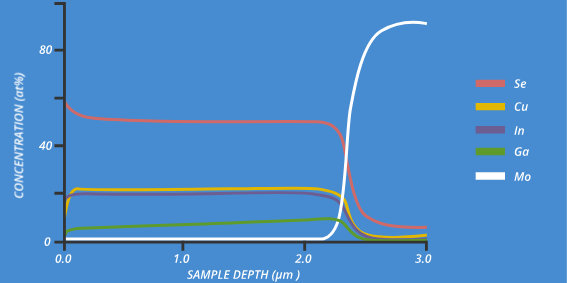

Compositional depth profile of a solar cell

Pulsed RF GD OES will answer in minutes – even seconds to multiple questions such as:

Multilayer PVD coating, evidence of C contamination at the interface