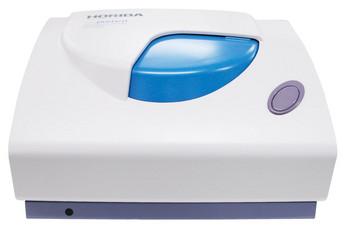

SA-9600 Series

BET Flowing Gas Surface Area Analyzers

The surface area of a material is, in many cases, as important as the chemical properties. As particle size decreases, surface area increases. Porosity of materials - from micropores to macropores - contribute even more to the total surface area. The interface at the surface is what defines how a solid reacts to other substances, be they gases, liquids, or solids.

Surface area can impact shelf life, stability, dissolution and efficacy of pharmaceutical powders and tablets. Likewise, surface area can affect the rheological properties and hiding powers of pigments, paints, and coatings. It has a significant impact on the ability for materials like catalysts, adsorbents, filtration materials and air separation products to react in the designed application. Ceramics used in applications ranging from; dinner plates, to dental implants, to electronics, all are affected by surface area.

While particle size is frequently used to control size reduction and milling of minerals and other substances, surface area can provide substantial size reduction feedback. Many times, a material which may have the same particle size across different batches may reveal completely different surface areas due to small changes in processing.

The HORIBA Solution

The SA-9600 series of surface area analyzers brings exceptional speed, convenience, and low cost-per-analysis to surface area measurement on a wide variety of materials. Now you can perform ultra-fast single or multi-point surface area measurements with push-button ease.

These tools use the robust and proven flowing gas method to acquire gas adsorption and desorption data. This information is then used to calculate total surface area utilizing the well-known BET method. The advantage of the flowing gas method is most evident in single-point mode where up to thirty sample analyses can be performed per hour.

The patented SA-9600 technology provides routine total surface area determination in as little as two to six minutes. The SA-9603 models feature three stations for three simultaneous surface area measurements.

Read more on the SA-9600 by visiting Featured Publications.

Manufacturing Company: HORIBA Scientific

Selection of countries and territories where this product is available:

Afghanistan,Antigua and Barbuda,Argentina,Armenia,Australia,Azerbaijan,Bahamas,Bangladesh,Barbados,Belize,Bhutan,Bolivia,Brazil,Brunei,Cambodia,Canada,Cayman Islands,Chile,China,Colombia,Costa Rica,Cote d'Ivoire,Dominica,Dominican Republic,Ecuador,El Salvador,French Guyana,French Polynesia,FYROM (North Macedonia),Grenada,Guadeloupe,Guatemala,Guyana,Haiti,Honduras,Hong Kong SAR of China,India,Indonesia,Jamaica,Japan,Kazakhstan,Korea (South),Kosovo,Kyrgiyz Republic,Laos,Malaysia,Maldives,Martinique,Mayotte,Mexico,Mongolia,Myanmar,Nepal,New Caledonia,New Zealand,Nicaragua,Pakistan,Panama,Paraguay,Peru,Philippines,Republic of the Congo,Reunion,Russia,Saint Helena,Saint Kitts and Nevis,Seychelles,Sierra Leone,Singapore,Sri Lanka,St. Lucia,St. Vincent and the Grenadinas,Suriname,Sweden,Switzerland,Taiwan,Tajikistan,Thailand,Trinidad and Tobago,Turkmenistan,United States,Uruguay,Uzbekistan,Venezuela,Vietnam

View the complete list

here.

This product is available in the following countries and territories:

- Afghanistan

- Antigua and Barbuda

- Argentina

- Armenia

- Australia

- Azerbaijan

- Bahamas

- Bangladesh

- Barbados

- Belize

- Bhutan

- Bolivia

- Brazil

- Brunei

- Cambodia

- Canada

- Cayman Islands

- Chile

- China

- Colombia

- Costa Rica

- Cote d'Ivoire

- Dominica

- Dominican Republic

- Ecuador

- El Salvador

- French Guyana

- French Polynesia

- FYROM (North Macedonia)

- Grenada

- Guadeloupe

- Guatemala

- Guyana

- Haiti

- Honduras

- Hong Kong SAR of China

- India

- Indonesia

- Jamaica

- Japan

- Kazakhstan

- Korea (South)

- Kosovo

- Kyrgiyz Republic

- Laos

- Malaysia

- Maldives

- Martinique

- Mayotte

- Mexico

- Mongolia

- Myanmar

- Nepal

- New Caledonia

- New Zealand

- Nicaragua

- Pakistan

- Panama

- Paraguay

- Peru

- Philippines

- Republic of the Congo

- Reunion

- Russia

- Saint Helena

- Saint Kitts and Nevis

- Seychelles

- Sierra Leone

- Singapore

- Sri Lanka

- St. Lucia

- St. Vincent and the Grenadinas

- Suriname

- Sweden

- Switzerland

- Taiwan

- Tajikistan

- Thailand

- Trinidad and Tobago

- Turkmenistan

- United States

- Uruguay

- Uzbekistan

- Venezuela

- Vietnam